If I ever do a reweld again, I am never going to weld the bolt into the receiver. The true cost of that became clear during final assembly. There are so many parts that require the bolt be moved out of battery in order to put them together.

Okay, sure, I could have simply omitted much of the unseen, internal hardware, and just fixed bits like the charging handle in place with epoxy. But I had come this far with real steel, it seemed a shame to do that.

Plus, if you are going that route, having a bolt-substitute that travels means you can cock and dry-fire.

The fake bolt got in my way not just in putting on the last parts, but even in drilling some of the last holes. It also stands just slightly proud where the magazine lips sit, and won't quite let the magazine go far enough in to engage the magazine catch. Which I could have fixed, but I really needed to finish this project and move on.

So here it is:

That out-of-period hex nut is my imperfect solution to securing the barrel shroud lever. In the original, the stem was pounded down to make a rivet. I milled the broken stub flat, drilled a hole, and tapped it for a metric stud, which is fixed in with Locktite.

For the top sight, I drilled for friction pins, but ended up seating them with Locktite too when the holes got a little chewed up. The fake bolt kept catching on the drill bit. So all in all, I spent about four hours on the mill, mostly using it as a stable platform to align everything for the last couple of mounting holes.

And here is a shot looking more-or-less from the good end (taken in poor light, sorry):

The repaired part more-or-less blends in; the rest of the metal is a pretty good mix, from the somewhat rust-colored barrel (with most of the factory bluing worn off) to the flat black paint on the magazine. And all of the other parts are original, and essentially un-touched by my process.

Tricks of the trade, discussion of design principles, and musings and rants about theater from a working theater technician/designer.

Showing posts with label suomi. Show all posts

Showing posts with label suomi. Show all posts

Monday, January 19, 2015

Saturday, January 17, 2015

The Blues

Last night I took the Suomi as far as was worthwhile with ever-finer grades of emery paper -- the last passes were wet-sanding with 400 grit, then a going over with 0000 steel wool.

There are deep scratches from the various machining and grinding processes that wouldn't go away unless I took almost a hundredth of an inch off. That, and there are remaining voids and pockets that aren't going to clean up anyhow. Plus some visible mis-alignment of several of the pieces. So this degree of polish would have to suffice.

Of course, it needs to look at least something like the other parts of the gun. I am actually not sure what process the Finns used on the originals -- probably a hot-bluing tank, but really could have been any number of processes. But rust never quite sleeps (it only grows lethargic) and the final look of the original hardware is a nice mixture of blue-black and rust brown.

After a lot of research online, it appears that at least some people have achieved a decent-looking period finish by combining Plum Brown with cold bluing. (Cold blue also doesn't wear well, but this is getting only small amounts of handling. It isn't as if anyone will be taking it to the range!)

The Plum is a strong acid. I degreased with hot soapy water and 70% alcohol, then put on a coat. Almost instantly the receiver turned a rich coppery brown:

I'll have to remember that in the future. It was also a remarkably even coat, especially considering the cap on the bottle broke and I got drips of the stuff all over the work table.

The Birchwood Casey Perma-Blue, on the other hand, went on very spotty. But I can't blame the liquid. I think it reacted with the layer of Plum Brown -- which is essentially red rust -- and perhaps with some of the water or even not-quite-deactivated Plum Brown.

But I wiped it on, let it sit for a few minutes, then rinsed in hot water. Rubbed off the loose material and buffed it up with steel wool, then did a second coat. This is where it stands at the moment:

The color match isn't bad. It needs more buffing out, and I'll want to go back with a Q-tip and touch up some spots that didn't get enough black. In life (as opposed to in photograph) it looks smoother, but a little lighter than the original part. But the final coat of gun oil is going to darken it, I'm sure. I'm also going to go back with steel wool and even emery paper to knock the bluing off some of the exposed edges -- weather it, in other words.

It looks like it is going to work. My major worry at this point is the treatment is too fragile and will get scratched up when I clamp into the mill to drill the last couple of holes.

There are deep scratches from the various machining and grinding processes that wouldn't go away unless I took almost a hundredth of an inch off. That, and there are remaining voids and pockets that aren't going to clean up anyhow. Plus some visible mis-alignment of several of the pieces. So this degree of polish would have to suffice.

Of course, it needs to look at least something like the other parts of the gun. I am actually not sure what process the Finns used on the originals -- probably a hot-bluing tank, but really could have been any number of processes. But rust never quite sleeps (it only grows lethargic) and the final look of the original hardware is a nice mixture of blue-black and rust brown.

After a lot of research online, it appears that at least some people have achieved a decent-looking period finish by combining Plum Brown with cold bluing. (Cold blue also doesn't wear well, but this is getting only small amounts of handling. It isn't as if anyone will be taking it to the range!)

The Plum is a strong acid. I degreased with hot soapy water and 70% alcohol, then put on a coat. Almost instantly the receiver turned a rich coppery brown:

I'll have to remember that in the future. It was also a remarkably even coat, especially considering the cap on the bottle broke and I got drips of the stuff all over the work table.

The Birchwood Casey Perma-Blue, on the other hand, went on very spotty. But I can't blame the liquid. I think it reacted with the layer of Plum Brown -- which is essentially red rust -- and perhaps with some of the water or even not-quite-deactivated Plum Brown.

But I wiped it on, let it sit for a few minutes, then rinsed in hot water. Rubbed off the loose material and buffed it up with steel wool, then did a second coat. This is where it stands at the moment:

The color match isn't bad. It needs more buffing out, and I'll want to go back with a Q-tip and touch up some spots that didn't get enough black. In life (as opposed to in photograph) it looks smoother, but a little lighter than the original part. But the final coat of gun oil is going to darken it, I'm sure. I'm also going to go back with steel wool and even emery paper to knock the bluing off some of the exposed edges -- weather it, in other words.

It looks like it is going to work. My major worry at this point is the treatment is too fragile and will get scratched up when I clamp into the mill to drill the last couple of holes.

Friday, January 16, 2015

Suomi Update

Welding is done on this project. It was a long but productive day at TechShop. Unfortunately I didn't stop to take any pictures.

First up was milling some scrap steel down to the correct thickness for the side plates. That meant figuring out how to use the t-slot clamps. Put the metal on a sacrificial piece of aluminium scrap and gingerly navigated an end mill around the clamps.

Once that was done, painted the scrap with "Prussian Blue" (layout fluid) and transferred the shape of the voids to it. I meant to bring in a pencil so I could do a rubbing on to scrap paper. But as it turns out, my hands were grimy enough from milling down steel I just needed to rub my fingers across the receiver to transfer the edges I needed to the paper templates.

Cut the bits out with the band saw, used grinding wheel and files to get the final fit, then superglued them in place.

Logged out of the mill and hopped on a vacant lathe; milled down a 1" chunk of aluminium rod to make a backer for the new welds I was going to be putting on the threaded end of the receiver tube. And fit the barrel plug back in to protect the space in front.

And then it was on to the MIG. I was getting good welds on a piece of scrap, so I didn't change the settings that were already on the machine. Welded the filler pieces for the side plates, tacked the front filler in place, filled a couple voids elsewhere.

So maybe aluminium backing is not the best choice. It took grinder, cold chisel, and pipe wrench to get the backing pieces back out again. But once they were out, clean-up in the voids they had filled was minimal, so perhaps it was a good thing after all.

The usual round of angle grinder, Dremel, then lots of hand files (I chose these because they are more accurate and allow me to get closer to a flat profile -- grinding tools tend to dish out).

I was very happy when the trigger group dropped back in. I thought the end cap was going to take a bit of work, but it also spun right on. The furniture is tight, though; I still need to remove some metal right near the magazine well. And even though there is visible warpage around the magazine well (some of which may be original, the remainder is probably largely from the demiliterization), the magazine catch and a test magazine both slide right in.

So most of what is left is drilling a few holes, final clean-up, and an attempt at bluing.

First up was milling some scrap steel down to the correct thickness for the side plates. That meant figuring out how to use the t-slot clamps. Put the metal on a sacrificial piece of aluminium scrap and gingerly navigated an end mill around the clamps.

Once that was done, painted the scrap with "Prussian Blue" (layout fluid) and transferred the shape of the voids to it. I meant to bring in a pencil so I could do a rubbing on to scrap paper. But as it turns out, my hands were grimy enough from milling down steel I just needed to rub my fingers across the receiver to transfer the edges I needed to the paper templates.

Cut the bits out with the band saw, used grinding wheel and files to get the final fit, then superglued them in place.

Logged out of the mill and hopped on a vacant lathe; milled down a 1" chunk of aluminium rod to make a backer for the new welds I was going to be putting on the threaded end of the receiver tube. And fit the barrel plug back in to protect the space in front.

And then it was on to the MIG. I was getting good welds on a piece of scrap, so I didn't change the settings that were already on the machine. Welded the filler pieces for the side plates, tacked the front filler in place, filled a couple voids elsewhere.

So maybe aluminium backing is not the best choice. It took grinder, cold chisel, and pipe wrench to get the backing pieces back out again. But once they were out, clean-up in the voids they had filled was minimal, so perhaps it was a good thing after all.

The usual round of angle grinder, Dremel, then lots of hand files (I chose these because they are more accurate and allow me to get closer to a flat profile -- grinding tools tend to dish out).

I was very happy when the trigger group dropped back in. I thought the end cap was going to take a bit of work, but it also spun right on. The furniture is tight, though; I still need to remove some metal right near the magazine well. And even though there is visible warpage around the magazine well (some of which may be original, the remainder is probably largely from the demiliterization), the magazine catch and a test magazine both slide right in.

So most of what is left is drilling a few holes, final clean-up, and an attempt at bluing.

Wednesday, January 14, 2015

More Suomi

Milled off more of the side plates today, and milled up a stand-in trigger group and magazine/magazine catch out of half-inch aluminium to keep weld metal out of the places where it shouldn't go:

Now all I have to do is cut the slices of steel that fill in the missing portions of the side plates, and mill those down so there will be less grinding and filing once they are in.

Of course I still need to cut a plug for the rear of the cylinder, fill the remaining gaps with weld metal, and grind that down so the end cap fits properly. Pain not being able to lathe it. Actually...I might just be able to lathe it if I leave the plug in...

After that, it is just grinding, dressing with files, etc., to get it as nice-looking as I can before bluing. Chase the hole for the magazine catch, drill the studs for the rear sight, and adapt the barrel shroud lever for bolting it in place. The rest is drift pins and lock-tite. Probably another 4-5 days of work.

I went to Techshop and all I brought back...

...was this little bit of metal:

This is the lower part of the Rear Filler; it sits between the magazine well and the trigger group and keeps the latter from falling out of the gun. That is, the complete part does. I didn't want to take apart the rear of the magazine well and rebuild all that from scratch, so I just milled out a space:

I was using the wrong end mill and pretty much getting everything else wrong (notice the groove in the side rails from an incautious pass after something slipped on me!) Which explains why getting this far was eight solid hours of machining.

Well, I did re-mill and clean up the slot where the sight sits. I haven't made up my mind whether I'll try tap holes for screws, or just press-fit brass pins which I can then hammer out as rivets.

Sigh. I'm trying to avoid cutting too close to the magazine well because the rear slot would be a real pain to clean up. But based on what it all looks like now, I think I need to mill those side rails in a little further to properly expose the slot where the new part goes. And, yes, I am tempted to cut the entire old part away, but this is all hardened steel and it would be very hard to align it in bandsaw or anything else more suited to deep cuts than the manual mill.

Yes; at this point I've learned enough about how the weapon goes together, and how to derive the various dimensions of the parts, that I could now start from raw materials and fashion one completely from scratch. In aluminium, that would almost certainly be faster than all the work I've done so far re-welding and trying to clean up.

(Or even steel -- especially since you can get parts and parts kits that include, intact, the magazine holder, trunnion, and even lugs -- leaving pretty much the rear part of the tube and the side rails to fashion from scratch).

This is the lower part of the Rear Filler; it sits between the magazine well and the trigger group and keeps the latter from falling out of the gun. That is, the complete part does. I didn't want to take apart the rear of the magazine well and rebuild all that from scratch, so I just milled out a space:

I was using the wrong end mill and pretty much getting everything else wrong (notice the groove in the side rails from an incautious pass after something slipped on me!) Which explains why getting this far was eight solid hours of machining.

Well, I did re-mill and clean up the slot where the sight sits. I haven't made up my mind whether I'll try tap holes for screws, or just press-fit brass pins which I can then hammer out as rivets.

Sigh. I'm trying to avoid cutting too close to the magazine well because the rear slot would be a real pain to clean up. But based on what it all looks like now, I think I need to mill those side rails in a little further to properly expose the slot where the new part goes. And, yes, I am tempted to cut the entire old part away, but this is all hardened steel and it would be very hard to align it in bandsaw or anything else more suited to deep cuts than the manual mill.

Yes; at this point I've learned enough about how the weapon goes together, and how to derive the various dimensions of the parts, that I could now start from raw materials and fashion one completely from scratch. In aluminium, that would almost certainly be faster than all the work I've done so far re-welding and trying to clean up.

(Or even steel -- especially since you can get parts and parts kits that include, intact, the magazine holder, trunnion, and even lugs -- leaving pretty much the rear part of the tube and the side rails to fashion from scratch).

Saturday, January 10, 2015

Computer-AIDED Design

There's still a trend in some circles to think of 3d printing, CNC, et al as being "too easy." That instead of all the work of carving and sanding and machining, you just "press a button."

Well, like the story of Basho and the Fish, getting to the point where you press that button is actually a lot of work. What these new tools are, is just another form of jig (or "tooling," if you want to use the fancy aerospace term).

I used a lot of jigs when I was a full-time theater carpenter (that is, a set builder). We'd spray-paint them red so they didn't get thrown out by accident. One show I had to make a whole bunch of fake bolt heads as decorations for some massive girders. Underside of a bridge or something; I don't remember now. Ripped down 1x to 2", cut it into 2" squares, cut off the corners to make a hex shape, then routed around the top. I spent most of a day making a complicated jig that would hold the thing in place for all the cuts and routes.

Which is the thing, here; if you save any time with 3d printing or CNC machining, it is when you are building multiple copies. The savings, if any, are one of those economies of scale. I could have scratch-built a V150 armored car in less time than it took to make the 3d model. But since the model was made, we've printed four or five of them (plus there's at least two others out in the world).

Which is the thing, here; if you save any time with 3d printing or CNC machining, it is when you are building multiple copies. The savings, if any, are one of those economies of scale. I could have scratch-built a V150 armored car in less time than it took to make the 3d model. But since the model was made, we've printed four or five of them (plus there's at least two others out in the world).

And, well, you'd think -- for all that computing power you have to throw behind the design process, it still takes horrendously long.

On the 3d side, I've been working on my M57 "Clacker" model to make it 3d-printable. Apparently, some people have used them to make an e-cigarette! Seems like it would be useful anyhow to work up as some sort of general-purpose button-powered prop. But low priority project. Also working on the V150 model again. Someone over at Shapeways has an interest in seeing it in 1/18th scale. Which requires a higher level of detail than is currently in the model, but I have also slowly been working it up as a Poser version anyhow, so that's been happening already.

On the 3d side, I've been working on my M57 "Clacker" model to make it 3d-printable. Apparently, some people have used them to make an e-cigarette! Seems like it would be useful anyhow to work up as some sort of general-purpose button-powered prop. But low priority project. Also working on the V150 model again. Someone over at Shapeways has an interest in seeing it in 1/18th scale. Which requires a higher level of detail than is currently in the model, but I have also slowly been working it up as a Poser version anyhow, so that's been happening already.

My old penlight finally died and I thought of yet another project that would be very cute. To wit; a penlight in the shape of a Sonic Screwdriver. But not any of the existing ones; a very small one built around a single AAA cell -- not the dual AA versions which won't fit in a pocket, or the ones using weird rare batteries that are a pain to replace. AAA, with a boost circuit driving half a watt of narrow-beam colored light (we almost always use colored light backstage. Tradition.)

But that requires going into the CAD software and figuring out a casing that can be printed or machined that fits the available components and looks at least something like the sonic of choice (I'm partial to a War Doctor sonic, myself, which is basically a Tom Baker sonic with a different top).

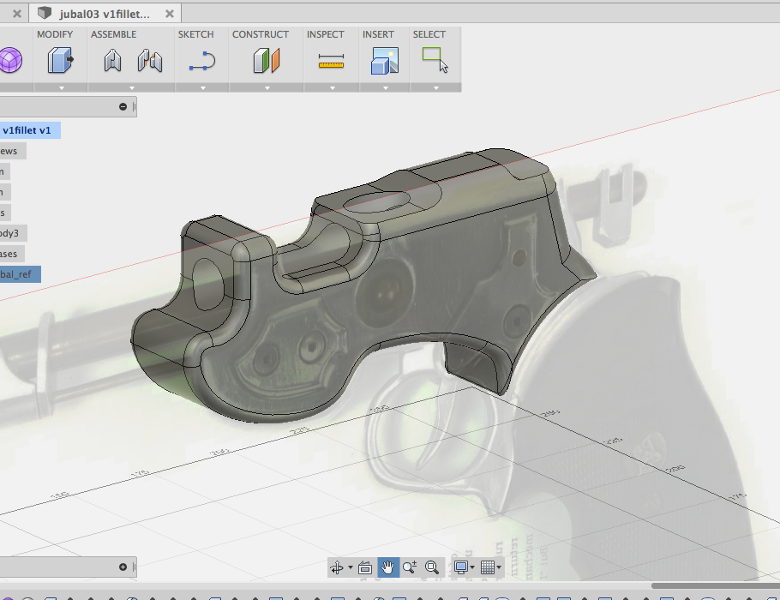

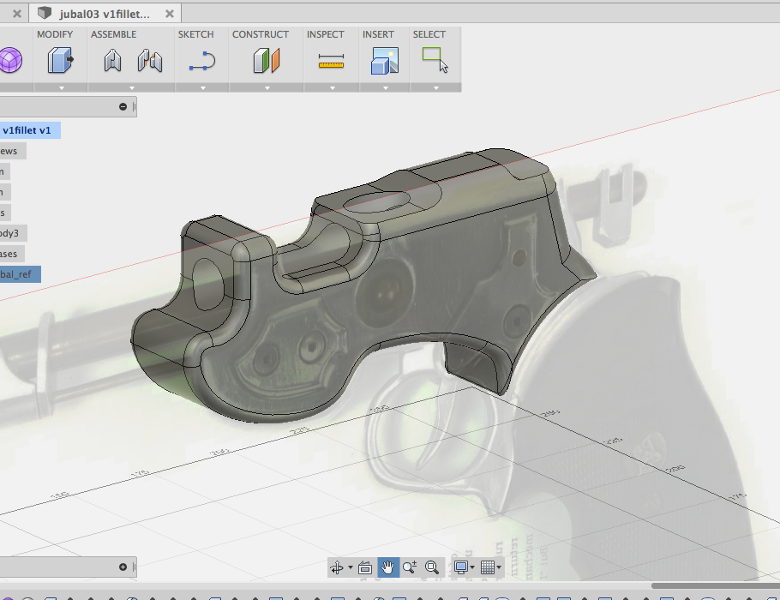

Also back on one of those rear burners is the Jubal Early CNC model. And a turned flash hider for a "King of the Rocketmen" pistol.

I just got another order for "Aliens" grenades. And since I'm overdue for it, going to revisit the process and some of the measurements. And purchase some new lathe tools. And that's not (mostly) on the computer, but I still think about building my own versions of some of the variant ammunition, and that's probably best done in a CAD application. With an eye towards printing, casting, or even perhaps injection molding custom caps.

I just got another order for "Aliens" grenades. And since I'm overdue for it, going to revisit the process and some of the measurements. And purchase some new lathe tools. And that's not (mostly) on the computer, but I still think about building my own versions of some of the variant ammunition, and that's probably best done in a CAD application. With an eye towards printing, casting, or even perhaps injection molding custom caps.

Although I need to order metal and tooling now, the priority machining task is finishing up the Suomi. I have been reading about silver solder and I think I might fill some of the smaller remaining voids with that and deal with the way it will alter the finish in those locations. They are mostly hidden anyhow, so I think it may be okay. Most of the work on this is pretty primitive, though. I did a lot of the milling entirely by eye. Heck -- I didn't even calculate my feeds and speeds, but just set up the mill by ear and instinct.

Although I need to order metal and tooling now, the priority machining task is finishing up the Suomi. I have been reading about silver solder and I think I might fill some of the smaller remaining voids with that and deal with the way it will alter the finish in those locations. They are mostly hidden anyhow, so I think it may be okay. Most of the work on this is pretty primitive, though. I did a lot of the milling entirely by eye. Heck -- I didn't even calculate my feeds and speeds, but just set up the mill by ear and instinct.

I've been really pushing on the DuckLight PCB -- working it up in Fritzing at the moment, which seems to be working and saves me the time of learning Eagle properly. Using the prototype in another show helped a lot. I'm getting excited about this thing and think it may be a very useful little trick for the prop-maker's arsenal.

I'm going with an ATtiny84 now. Four channels of software PWM current-controlled to 350ma means you can run a cheap RGB "Cree" LED, an RGBW, or a single-channel LED of up to three watts in bridging mode. ICSP header for the experienced programmer, software serial I/O...and there's enough I/O pins left on the '84 to put in a Program Select button. So the end-user can dial up a bunch of basic effects right on the board, without needing to connect up a computer. The XBee option will be on a daughterboard, though; there's just no space for the pin footprint.

I fully intend this to be offered in kit form. And at this point I've solved enough of the electronics and programming issues I really am ready to make up the first batch of PCB's.

If that wasn't enough light, I have a second order for the LED stage lights I built. Now I just need to get the client to pay a little better piece-work for assembling them...

If that wasn't enough light, I have a second order for the LED stage lights I built. Now I just need to get the client to pay a little better piece-work for assembling them...

Well, like the story of Basho and the Fish, getting to the point where you press that button is actually a lot of work. What these new tools are, is just another form of jig (or "tooling," if you want to use the fancy aerospace term).

I used a lot of jigs when I was a full-time theater carpenter (that is, a set builder). We'd spray-paint them red so they didn't get thrown out by accident. One show I had to make a whole bunch of fake bolt heads as decorations for some massive girders. Underside of a bridge or something; I don't remember now. Ripped down 1x to 2", cut it into 2" squares, cut off the corners to make a hex shape, then routed around the top. I spent most of a day making a complicated jig that would hold the thing in place for all the cuts and routes.

Which is the thing, here; if you save any time with 3d printing or CNC machining, it is when you are building multiple copies. The savings, if any, are one of those economies of scale. I could have scratch-built a V150 armored car in less time than it took to make the 3d model. But since the model was made, we've printed four or five of them (plus there's at least two others out in the world).

Which is the thing, here; if you save any time with 3d printing or CNC machining, it is when you are building multiple copies. The savings, if any, are one of those economies of scale. I could have scratch-built a V150 armored car in less time than it took to make the 3d model. But since the model was made, we've printed four or five of them (plus there's at least two others out in the world).And, well, you'd think -- for all that computing power you have to throw behind the design process, it still takes horrendously long.

On the 3d side, I've been working on my M57 "Clacker" model to make it 3d-printable. Apparently, some people have used them to make an e-cigarette! Seems like it would be useful anyhow to work up as some sort of general-purpose button-powered prop. But low priority project. Also working on the V150 model again. Someone over at Shapeways has an interest in seeing it in 1/18th scale. Which requires a higher level of detail than is currently in the model, but I have also slowly been working it up as a Poser version anyhow, so that's been happening already.

On the 3d side, I've been working on my M57 "Clacker" model to make it 3d-printable. Apparently, some people have used them to make an e-cigarette! Seems like it would be useful anyhow to work up as some sort of general-purpose button-powered prop. But low priority project. Also working on the V150 model again. Someone over at Shapeways has an interest in seeing it in 1/18th scale. Which requires a higher level of detail than is currently in the model, but I have also slowly been working it up as a Poser version anyhow, so that's been happening already.My old penlight finally died and I thought of yet another project that would be very cute. To wit; a penlight in the shape of a Sonic Screwdriver. But not any of the existing ones; a very small one built around a single AAA cell -- not the dual AA versions which won't fit in a pocket, or the ones using weird rare batteries that are a pain to replace. AAA, with a boost circuit driving half a watt of narrow-beam colored light (we almost always use colored light backstage. Tradition.)

But that requires going into the CAD software and figuring out a casing that can be printed or machined that fits the available components and looks at least something like the sonic of choice (I'm partial to a War Doctor sonic, myself, which is basically a Tom Baker sonic with a different top).

Also back on one of those rear burners is the Jubal Early CNC model. And a turned flash hider for a "King of the Rocketmen" pistol.

I just got another order for "Aliens" grenades. And since I'm overdue for it, going to revisit the process and some of the measurements. And purchase some new lathe tools. And that's not (mostly) on the computer, but I still think about building my own versions of some of the variant ammunition, and that's probably best done in a CAD application. With an eye towards printing, casting, or even perhaps injection molding custom caps.

I just got another order for "Aliens" grenades. And since I'm overdue for it, going to revisit the process and some of the measurements. And purchase some new lathe tools. And that's not (mostly) on the computer, but I still think about building my own versions of some of the variant ammunition, and that's probably best done in a CAD application. With an eye towards printing, casting, or even perhaps injection molding custom caps. Although I need to order metal and tooling now, the priority machining task is finishing up the Suomi. I have been reading about silver solder and I think I might fill some of the smaller remaining voids with that and deal with the way it will alter the finish in those locations. They are mostly hidden anyhow, so I think it may be okay. Most of the work on this is pretty primitive, though. I did a lot of the milling entirely by eye. Heck -- I didn't even calculate my feeds and speeds, but just set up the mill by ear and instinct.

Although I need to order metal and tooling now, the priority machining task is finishing up the Suomi. I have been reading about silver solder and I think I might fill some of the smaller remaining voids with that and deal with the way it will alter the finish in those locations. They are mostly hidden anyhow, so I think it may be okay. Most of the work on this is pretty primitive, though. I did a lot of the milling entirely by eye. Heck -- I didn't even calculate my feeds and speeds, but just set up the mill by ear and instinct.I've been really pushing on the DuckLight PCB -- working it up in Fritzing at the moment, which seems to be working and saves me the time of learning Eagle properly. Using the prototype in another show helped a lot. I'm getting excited about this thing and think it may be a very useful little trick for the prop-maker's arsenal.

I'm going with an ATtiny84 now. Four channels of software PWM current-controlled to 350ma means you can run a cheap RGB "Cree" LED, an RGBW, or a single-channel LED of up to three watts in bridging mode. ICSP header for the experienced programmer, software serial I/O...and there's enough I/O pins left on the '84 to put in a Program Select button. So the end-user can dial up a bunch of basic effects right on the board, without needing to connect up a computer. The XBee option will be on a daughterboard, though; there's just no space for the pin footprint.

I fully intend this to be offered in kit form. And at this point I've solved enough of the electronics and programming issues I really am ready to make up the first batch of PCB's.

If that wasn't enough light, I have a second order for the LED stage lights I built. Now I just need to get the client to pay a little better piece-work for assembling them...

If that wasn't enough light, I have a second order for the LED stage lights I built. Now I just need to get the client to pay a little better piece-work for assembling them...Thursday, December 4, 2014

KP Duty

Spent a full day at TechShop milling, grinding, and most especially filing. It looks like all the parts from the parts kit will more-or-less fit:

The shroud retaining lever fits, but the shaft was sheered near where the nut would be. Right now it is a tight friction fit but if I want to be really nice, I need to cut off the shaft, press-fit a new one, and thread that for a new retaining nut.

The magazine catch release appears to fit in the existing slot, with the pin being press-fit. At the very least I have to re-drill the holes, as one got slagged over.

The charging handle appears to be assembled through the gun, with the bolt catcher also pinned on. Sounds very fiddly to do! (I don't even know how you can press the -- missing -- pin in once the side rails are welded on).

I just figured it out. There's a hole in the side plates that is drilled slightly larger than the retaining pin. Trouble is, this requires moving the bolt back slightly from out of battery -- something no longer possible since I welded it in. But I should be able to just mill the slot a bit further and make it work.

The sight was wrenched off but even straightened, the remains of the rivets do not appear to be located properly. So I'll need to grind those off, possibly re-mill the slot a little to achieve a proper fit, then drill new holes. Which I might want to tap, or use soft brass on, so the next person along doesn't have to lever the sight assembly off.

The trigger assembly is held at the front by a block with a notch in it; only the stub of this block remains as the rest was in the direct path of the cut. So I have a few hours yet -- among other things, cleaning off the cosmoleum or whatever it is on the remaining original parts so they fit and move properly.

On the receiver itself: it is never going to look pristine, and I spent all morning with diamond bit and small hand files just re-shaping the barrel lugs after my last attempt to fill some of the remaining voids. But at the same time, it is starting to look decent and it might just be worth trying to fill the two worst gaps; the remaining slot in the side plates, and the small gaps to either side of the end cap. The latter are visible when the weapon is assembled.

To do the latter, I'll want to lathe up a new backing plug from the last of my 1-1/4" aluminium rod. Although since the bolt is now a permanent part of the rebuilt receiver, there's no good reason to keep any more of the rear clear than is needed for the rod that is part of the end cap. The big downside is I'm sure to damage the threads again, and have to grind and file those some more.

The side plates are a bit more troublesome. I had a long and difficult time trimming weld metal that made it past the end of my last set of backing plates, so I'm leery of welding near the tube. But pretty much, would be milling a chunk of aluminium plate to stand in for the trigger group. And probably milling into the existing side plates to provide a slot for fresh pieces of steel. The MIG will fill a lot, but even with a backing plate, where I fill is where I'm going to have to go back with mill and grinding bits to clean out the slot again.

I'm reading up on prep for gun bluing now. I have both brown and blue and should be able to get a nice aged patina out of them. I suspect very strongly I'm going to have to spend 10-20 hours continuing to file things smoother and smoother, then graduate to finer and finer emery papers, then finally to steel wool and wire brushes. So there's a bit of labor involved, still!

The shroud retaining lever fits, but the shaft was sheered near where the nut would be. Right now it is a tight friction fit but if I want to be really nice, I need to cut off the shaft, press-fit a new one, and thread that for a new retaining nut.

The magazine catch release appears to fit in the existing slot, with the pin being press-fit. At the very least I have to re-drill the holes, as one got slagged over.

The charging handle appears to be assembled through the gun, with the bolt catcher also pinned on. Sounds very fiddly to do! (I don't even know how you can press the -- missing -- pin in once the side rails are welded on).

I just figured it out. There's a hole in the side plates that is drilled slightly larger than the retaining pin. Trouble is, this requires moving the bolt back slightly from out of battery -- something no longer possible since I welded it in. But I should be able to just mill the slot a bit further and make it work.

The sight was wrenched off but even straightened, the remains of the rivets do not appear to be located properly. So I'll need to grind those off, possibly re-mill the slot a little to achieve a proper fit, then drill new holes. Which I might want to tap, or use soft brass on, so the next person along doesn't have to lever the sight assembly off.

The trigger assembly is held at the front by a block with a notch in it; only the stub of this block remains as the rest was in the direct path of the cut. So I have a few hours yet -- among other things, cleaning off the cosmoleum or whatever it is on the remaining original parts so they fit and move properly.

On the receiver itself: it is never going to look pristine, and I spent all morning with diamond bit and small hand files just re-shaping the barrel lugs after my last attempt to fill some of the remaining voids. But at the same time, it is starting to look decent and it might just be worth trying to fill the two worst gaps; the remaining slot in the side plates, and the small gaps to either side of the end cap. The latter are visible when the weapon is assembled.

To do the latter, I'll want to lathe up a new backing plug from the last of my 1-1/4" aluminium rod. Although since the bolt is now a permanent part of the rebuilt receiver, there's no good reason to keep any more of the rear clear than is needed for the rod that is part of the end cap. The big downside is I'm sure to damage the threads again, and have to grind and file those some more.

The side plates are a bit more troublesome. I had a long and difficult time trimming weld metal that made it past the end of my last set of backing plates, so I'm leery of welding near the tube. But pretty much, would be milling a chunk of aluminium plate to stand in for the trigger group. And probably milling into the existing side plates to provide a slot for fresh pieces of steel. The MIG will fill a lot, but even with a backing plate, where I fill is where I'm going to have to go back with mill and grinding bits to clean out the slot again.

I'm reading up on prep for gun bluing now. I have both brown and blue and should be able to get a nice aged patina out of them. I suspect very strongly I'm going to have to spend 10-20 hours continuing to file things smoother and smoother, then graduate to finer and finer emery papers, then finally to steel wool and wire brushes. So there's a bit of labor involved, still!

Tuesday, December 2, 2014

One-Piece

I welded today.

Took the SBU (Safety and Basic Use class) for the MIG welder last week. Went in today and pulled a bunch of scrap (mostly battered welding chits from previous classes) from the bin and tried to remember what I'd learned in class. I'd had a lot of trouble in class for some reason. I think because previous experience in stick welding had me used to eyeballing the arc, and the bulk of the MIG electrode holder means you really can't do it that way. So fifteen years of muscle memory was in my way.

I messed with the dial settings and made lots of nasty spots and sputters for about an hour, then it started to click. The "bacon" sound came almost immediately upon achieving a good spark coil sound (the two sounds are superimposed; you can hear when you are getting a good weld). And once I found that groove, I could pretty arbitrarily change the electrode distance and travel speed, pretty much adjusting one to the other.

It is a whole dance when you are doing it right; maintaining the arc, building and pushing the puddle, achieving the right blend of penetration and fill, controlling the heat build-up. All through constant movement whilst maintaining the correct distance and travel.

Put rougher scrap on the table and started at welding into corners and filling voids. And it was going well enough I jumped right up to working on the Suomi again.

It is nice to finally have the receiver in one piece. There's a lot of grinding and filing before I can be sure I got the measurements right, though. And I haven't decided on the best way to tackle that hole behind the magazine well. I could mill a backing plate out of aluminium plate and fill the remaining void with weld metal. Or I could cut a slot and put in new steel. Or perhaps I can mill down the stubs of the side rails enough to where I can slot in new chunks of plate steel -- probably again with a backing plate of aluminium.

I also think I have to lathe another "fake bolt" to use as a backing plate to put a little more metal at the end of the tube; the cap screws down only so far and the gaps I have would be visible in the assembled weapon. The original fake bolt I machined is of course welded permanently inside the tube at this point, and I intend to take further steps to ensure it remains so.

There's still several smaller gaps. I tried flowing solder into some of the smallest holes but my iron hasn't got the power to push heat into five pounds of steel. There's also an epoxy-based filler designed for this, but it doesn't take bluing well. I have a small brazing kit, too, but unless I get in on the TIG class some time real soon I'm looking at basically throwing big blobs of metal from the oversized wire we have and then grinding them back down again. And it may take multiple passes before I'm satisfied with it.

In any case, TechShop was very much the way to go. Sturdy steel tables, lots of clamping options, a full-sized MIG of course, and lots of bandsaws and grinders and whatnot right there to create filler with. Much more comfortable than the plywood propped up on sawhorses out in a parking lot that I started with!

It is nice to finally have the receiver in one piece. There's a lot of grinding and filing before I can be sure I got the measurements right, though. And I haven't decided on the best way to tackle that hole behind the magazine well. I could mill a backing plate out of aluminium plate and fill the remaining void with weld metal. Or I could cut a slot and put in new steel. Or perhaps I can mill down the stubs of the side rails enough to where I can slot in new chunks of plate steel -- probably again with a backing plate of aluminium.

I also think I have to lathe another "fake bolt" to use as a backing plate to put a little more metal at the end of the tube; the cap screws down only so far and the gaps I have would be visible in the assembled weapon. The original fake bolt I machined is of course welded permanently inside the tube at this point, and I intend to take further steps to ensure it remains so.

There's still several smaller gaps. I tried flowing solder into some of the smallest holes but my iron hasn't got the power to push heat into five pounds of steel. There's also an epoxy-based filler designed for this, but it doesn't take bluing well. I have a small brazing kit, too, but unless I get in on the TIG class some time real soon I'm looking at basically throwing big blobs of metal from the oversized wire we have and then grinding them back down again. And it may take multiple passes before I'm satisfied with it.

In any case, TechShop was very much the way to go. Sturdy steel tables, lots of clamping options, a full-sized MIG of course, and lots of bandsaws and grinders and whatnot right there to create filler with. Much more comfortable than the plywood propped up on sawhorses out in a parking lot that I started with!

Came home, and my laptop was showing that it was on battery. With the charger plugged in. Oops. Looked at the charger, and there was a nasty charred spot in the cord where somehow it had cracked or been caught (or nibbled?) and tore the outer wrap-around conductor. Which apparently is not a ground/shield; there's power running through it. Hrm. Anyhow, was able to work a length of desoldering braid into the frayed ends and restore continuity. Good thing, too, since closing weekend is almost on us and all my sound cues and keyboard patches and house music are on this machine!

To finish up the day, plugged the UMX-610 into a Reaper file I keep for that purpose and did a little piano practice. But what did I say about muscle memory? Maybe welding all day tuned my hands to the wrong expectations. I was fumbling a lot of notes. But oh well. I do far too many things to even hope to do all of them well.

Thursday, November 13, 2014

Hedgehog Renewed

Right, so no more grinding at home -- I'll do that at TechShop. And no more welding with the flux-core wire welder; I'll take the SBU on the MIG at TechShop and use that instead. A good choice anyhow, as it is more convenient, and MIG allows me to weld on aluminium.

But on impulse I took the grinder to the new piece anyhow, just to see how bad it was. And I'm glad I did. Because I've got enough done now for a trial fit-up.

And that's a real confidence booster:

Feels pretty solid already, even though the receiver is still in two pieces, held together only by the fake bolt. And surprisingly heavy -- this is no Rambo one-handed wield (and I say this as a former M60 gunner, too!)

(And, no, this is not and will never be a functional firearm. For one thing, I lack the gunsmithing skills to achieve the tolerances and the quality of welds, much less little details like heat treating. Even less do I have skills necessary to make a fully legal semi-automatic weapon -- as cool as that might be. In short, I could just barely -- if I chose -- make something dangerous to shoot and illegal to own, and I have no intention of going in that direction.)

(933(r) et al gets rather complicated. The gist is that since 1986 no "new" machine gun can be created or imported into the US, and it is the receiver that makes it a machine gun. What I have right now is still, legally, "steel scrap" and non-regulated. But the instant I complete the last weld, I have by law created a machine gun -- unless I take steps first to make sure that it can not be, in the language of the BATF, "easily converted into" a functional weapon. Which language appears to be defined in practice as "...in about eight hours by someone with a fully-equipped machine shop.")

(Since I'm switching to MIG now, I will be able to weld the fake bolt in place. That should satisfy; someone would have to cut it up at least as much as the original demill in order to salvage it -- and at that point it would legally become scrap again.)

(933(r) et al gets rather complicated. The gist is that since 1986 no "new" machine gun can be created or imported into the US, and it is the receiver that makes it a machine gun. What I have right now is still, legally, "steel scrap" and non-regulated. But the instant I complete the last weld, I have by law created a machine gun -- unless I take steps first to make sure that it can not be, in the language of the BATF, "easily converted into" a functional weapon. Which language appears to be defined in practice as "...in about eight hours by someone with a fully-equipped machine shop.")

(Since I'm switching to MIG now, I will be able to weld the fake bolt in place. That should satisfy; someone would have to cut it up at least as much as the original demill in order to salvage it -- and at that point it would legally become scrap again.)

Wednesday, November 12, 2014

Alas, Poor Hedgehog

The next weld did not go as well. I still can't see what I'm doing, and still ended up with a lot of voids. Worse, I got a spot of weld metal on the end cap, which worked its way into the threads, and there was nothing for it but to twist the thing off anyhow...stripping the threads in the process. Fortunately, this is just the receiver threads (the end cap is made of sterner stuff. Or at least, it is now, having not been brought to annealing temperature by the original plasma cuts and the more recent welding.)

Anyhow, freeing the cap took tools and time I didn't have at the theater, so I gave up welding for the day and took it home. With the second piece tacked on, I now have enough to properly space the last weld. And it looks like a very large fill involved there (the plasma torch seems to have cut, backed off, then cut again at a slightly different angle, leaving a really large gap). I'm not sure puddling flux-core wire in there is the best move. I'm thinking I really do need to switch to MIG.

The next MIG class is a week from today. Now I just have to figure out how to restart my TechShop membership and still have money left for bills....

Anyhow, freeing the cap took tools and time I didn't have at the theater, so I gave up welding for the day and took it home. With the second piece tacked on, I now have enough to properly space the last weld. And it looks like a very large fill involved there (the plasma torch seems to have cut, backed off, then cut again at a slightly different angle, leaving a really large gap). I'm not sure puddling flux-core wire in there is the best move. I'm thinking I really do need to switch to MIG.

The next MIG class is a week from today. Now I just have to figure out how to restart my TechShop membership and still have money left for bills....

Tuesday, November 11, 2014

You've Got to Grind, Grind Grind at That Hedgehog...

Back to the Suomi. To recap; it started as a demilitarized kit, meaning all original parts except someone at the ATF took a plasma torch to the receiver. I ground off all the slag from the bits of receiver, and machined a jig (in the form of a fake bolt with a barrel plug attached to the front) out of aluminium.

Yesterday, I tried the first welds. One of the theaters I work at has one of those cheap wire-feed welders -- the ones that will plug into a household wall outlet. And I made a nice hedgehog.

(In my defense, besides being rusty, and more used to stick welding anyhow, I didn't have good light and could only really see the arc -- which is not quite enough to really see by.)

(This isn't the full hedgehog glory; I've already knocked off some of the slag and given it a quick wire brush.)

And it seemed to work. I was worried about filling the wide gaps, and worried about the aluminium backing. Well, the latter survived without real issue, and I was able to remove the most-stuck one with a few twists of a wrench. The former, it turned out bridging was relatively easy, but I didn't get as much metal down inside the gaps as I would like.

Flux-core wire is very slaggy stuff, and you tend to get a lot of voids and inclusions with it. I made it a point of puddling until I could see metal glowing (about the only thing I could see!) and that seems to have floated much of the slag to the surface.

And then to grinding -- mostly Dremel so far, plus a whole bunch of hand file work. I expected this to be the worst bit; the plasma torch cut is right across where the lugs mate with the rest of it. And it turned out I'd made one mistake in alignment; I put the piece in about 1/16th of an inch too close, meaning I had negative headspace.

But it made it all the same. Barrel and shroud sit tight and feel solid. Now to do the other two welds!

(Post title is a reference to one of the songs in "Mary Poppins" -- in fact, my favorite in terms of the orchestration. There's just this lovely little period brass oompah going on under that one.)

Yesterday, I tried the first welds. One of the theaters I work at has one of those cheap wire-feed welders -- the ones that will plug into a household wall outlet. And I made a nice hedgehog.

(In my defense, besides being rusty, and more used to stick welding anyhow, I didn't have good light and could only really see the arc -- which is not quite enough to really see by.)

(This isn't the full hedgehog glory; I've already knocked off some of the slag and given it a quick wire brush.)

And it seemed to work. I was worried about filling the wide gaps, and worried about the aluminium backing. Well, the latter survived without real issue, and I was able to remove the most-stuck one with a few twists of a wrench. The former, it turned out bridging was relatively easy, but I didn't get as much metal down inside the gaps as I would like.

Flux-core wire is very slaggy stuff, and you tend to get a lot of voids and inclusions with it. I made it a point of puddling until I could see metal glowing (about the only thing I could see!) and that seems to have floated much of the slag to the surface.

And then to grinding -- mostly Dremel so far, plus a whole bunch of hand file work. I expected this to be the worst bit; the plasma torch cut is right across where the lugs mate with the rest of it. And it turned out I'd made one mistake in alignment; I put the piece in about 1/16th of an inch too close, meaning I had negative headspace.

But it made it all the same. Barrel and shroud sit tight and feel solid. Now to do the other two welds!

(Post title is a reference to one of the songs in "Mary Poppins" -- in fact, my favorite in terms of the orchestration. There's just this lovely little period brass oompah going on under that one.)

Sunday, October 12, 2014

Tool-Time

Finished my second day at the mill. As I've said, tooling can be hit-or-miss at TechShop, They do however have two boxes of end mills, and they were in good shape when I checked them out. So no problem at all milling the wider slots in my Suomi bolt.

The narrow slot that rides into the chamber was another matter. This is about 3/32 wide and a good .2" deep. Just getting the piece set up was interesting enough; I ended up with a stack of parallels to raise the bolt up sufficiently for quill clearance, with another one slipped in against the previously milled flat in order to achieve the 90-degree alignment I needed for the last slot.

I purchased a 1/16th end mill with a tapered shank (the only thing they had close to the right size) for this, and that was a bit scary. Put the RPMs up to 3800, used the paper trick to get the height. According to my very rough calculations, my cut depth should be around five thous per pass, and my feed rate "really slow."

I purchased a 1/16th end mill with a tapered shank (the only thing they had close to the right size) for this, and that was a bit scary. Put the RPMs up to 3800, used the paper trick to get the height. According to my very rough calculations, my cut depth should be around five thous per pass, and my feed rate "really slow."

There was no chatter or smoking coolant, so after a dozen passes I increased to ten thou per pass and a comfortable feed rate. Doing this by hand, and being careful to advance at a steady rate and not slam my tiny fragile end mill.

Widening the slot I was down to less than a quarter of the mill diameter so I could afford to stick a lot more length in there. That went quickly.

And the bolt fit. A little looser than I'd like, but I'm ready for welding now.

I also had a last grenade to run off -- slightly smaller dimensions overall so it would fit properly in an Airsoft shotgun. I thought I had a chunk of 7075 left but the small chips and lack of sound told me this was more of the 2011. (The main differences I noticed working 6061 is longer, better-formed chips, and a tendency to "sing" -- vibration noise.)

Unfortunately, the cross-feed gear was not engaging correctly -- it was as if it had a backlash of half an inch or so -- and I couldn't make accurate cuts (also, the runout was on the order of 60 thous). So I contacted staff, they took a look and said they'd probably have to order parts. And I waited for a user to clear the other lathe and hopped on that one when he was done.

And mucked up several of my cuts. I'd gotten too used to the mill or something and was consistently over-shooting. And I hope I cut it small enough so it will work.

The funny part is, though -- the guy on the other lathe? He was working from my Instructable!

The narrow slot that rides into the chamber was another matter. This is about 3/32 wide and a good .2" deep. Just getting the piece set up was interesting enough; I ended up with a stack of parallels to raise the bolt up sufficiently for quill clearance, with another one slipped in against the previously milled flat in order to achieve the 90-degree alignment I needed for the last slot.

I purchased a 1/16th end mill with a tapered shank (the only thing they had close to the right size) for this, and that was a bit scary. Put the RPMs up to 3800, used the paper trick to get the height. According to my very rough calculations, my cut depth should be around five thous per pass, and my feed rate "really slow."

I purchased a 1/16th end mill with a tapered shank (the only thing they had close to the right size) for this, and that was a bit scary. Put the RPMs up to 3800, used the paper trick to get the height. According to my very rough calculations, my cut depth should be around five thous per pass, and my feed rate "really slow."There was no chatter or smoking coolant, so after a dozen passes I increased to ten thou per pass and a comfortable feed rate. Doing this by hand, and being careful to advance at a steady rate and not slam my tiny fragile end mill.

Widening the slot I was down to less than a quarter of the mill diameter so I could afford to stick a lot more length in there. That went quickly.

And the bolt fit. A little looser than I'd like, but I'm ready for welding now.

I also had a last grenade to run off -- slightly smaller dimensions overall so it would fit properly in an Airsoft shotgun. I thought I had a chunk of 7075 left but the small chips and lack of sound told me this was more of the 2011. (The main differences I noticed working 6061 is longer, better-formed chips, and a tendency to "sing" -- vibration noise.)

Unfortunately, the cross-feed gear was not engaging correctly -- it was as if it had a backlash of half an inch or so -- and I couldn't make accurate cuts (also, the runout was on the order of 60 thous). So I contacted staff, they took a look and said they'd probably have to order parts. And I waited for a user to clear the other lathe and hopped on that one when he was done.

And mucked up several of my cuts. I'd gotten too used to the mill or something and was consistently over-shooting. And I hope I cut it small enough so it will work.

The funny part is, though -- the guy on the other lathe? He was working from my Instructable!

Friday, October 10, 2014

Milling around?

No, lathing a round. Milling a flat.

Used the (manual) milling machine today for the first time since my introductory class. Didn't quite finish all the cuts I need on the fake bolt for the Suomi -- so I probably won't be able to do the first trial weld tomorrow.

But I did use the mill successfully, without breaking anything. Now back to the books to refresh my memory on climb cutting, speeds and feeds, correct RPM for the edge-finder, etc.

The fake bolt is the top piece. The bottom is turned to the outside diameter of the barrel and pegs into the face of the bolt during the welding operation to keep the lugs aligned. Later I may replace it with a piece turned to the inside dimension of the barrel for more barrel support, but I might have to replace the turned peg with a steel rod for strength.

I also got a piece of 1/4" plate. I just might be able to do a quick run on the Tormach CNC mill -- the biggest problem right now, though, is that the desk is out of ball nose end mills. So I could do something that was a cut-out, but curved 3D shapes are not going to work well. Not until either they restock or I can order my own from McMaster-Carr.

Used the (manual) milling machine today for the first time since my introductory class. Didn't quite finish all the cuts I need on the fake bolt for the Suomi -- so I probably won't be able to do the first trial weld tomorrow.

But I did use the mill successfully, without breaking anything. Now back to the books to refresh my memory on climb cutting, speeds and feeds, correct RPM for the edge-finder, etc.

The fake bolt is the top piece. The bottom is turned to the outside diameter of the barrel and pegs into the face of the bolt during the welding operation to keep the lugs aligned. Later I may replace it with a piece turned to the inside dimension of the barrel for more barrel support, but I might have to replace the turned peg with a steel rod for strength.

I also got a piece of 1/4" plate. I just might be able to do a quick run on the Tormach CNC mill -- the biggest problem right now, though, is that the desk is out of ball nose end mills. So I could do something that was a cut-out, but curved 3D shapes are not going to work well. Not until either they restock or I can order my own from McMaster-Carr.

Wednesday, October 8, 2014

Props Progress

Suomi --

The first pieces are cleaned and ready for welding. I've found a wire welder at one of my theaters that I can use. Not neat or strong, but okay for filling; techies often describe them as "hot gluing with metal."

What's going to make it more plausible is the permanent jig. The piece of aluminium up there is standing in for a fake bolt I'm turning out of 1.25" aluminium. That will hold all the pieces together for welding and remain in place as part of the finished prop. As an additional advantage, it will look like a closed bolt when viewed through the ejection port.

Jubal Early --

Finding the correct dimensions for the frame was a matter of successive approximation. First I stuffed paper in there and used a graphite pencil to rub the edges. Then transferred that to foam-core. Adjusted the foam-core and transferred to MDF.

The last cut was in 3/8" basswood, which appears to be slightly wider than is correct. A lot of sanding and adjustment, and I finally had a mock frame that the Pachmayr grips fit properly.

Next is scanning or photographing. And it is unfortunately obvious that the grip other people are claiming is correct, is slightly different.

But I might blame Pachmayr. They are rather inconsistent about keeping the same names across different frames. (The different shapes visible here are not an artifact of that. That's an accurate depiction of the cut-out void inside the grip itself).

However, all of this does underline how uncertain my references are. I am sure I can get the final gun to look very close to the screen shots. But I am equally sure that the first prototype is going to involve at least some filing and sanding (and translating corrections back to the original CAD files.)

It's also not cheap. The top part is a slab of aluminium a full inch deep. A nice working size from Online Metals comes out to thirty bucks. So adding the stock for the rest of it, brass tubes and al, over a hundred bucks of metal and hardware. Then add the cost of how many end mills I may be destroying in order to cut that much.

On the other hand, an all-metal PPG is currently selling for over $900. So I think I can probably do this economically enough to be worthwhile.

The first pieces are cleaned and ready for welding. I've found a wire welder at one of my theaters that I can use. Not neat or strong, but okay for filling; techies often describe them as "hot gluing with metal."

What's going to make it more plausible is the permanent jig. The piece of aluminium up there is standing in for a fake bolt I'm turning out of 1.25" aluminium. That will hold all the pieces together for welding and remain in place as part of the finished prop. As an additional advantage, it will look like a closed bolt when viewed through the ejection port.

Jubal Early --

Finding the correct dimensions for the frame was a matter of successive approximation. First I stuffed paper in there and used a graphite pencil to rub the edges. Then transferred that to foam-core. Adjusted the foam-core and transferred to MDF.

The last cut was in 3/8" basswood, which appears to be slightly wider than is correct. A lot of sanding and adjustment, and I finally had a mock frame that the Pachmayr grips fit properly.

Next is scanning or photographing. And it is unfortunately obvious that the grip other people are claiming is correct, is slightly different.

But I might blame Pachmayr. They are rather inconsistent about keeping the same names across different frames. (The different shapes visible here are not an artifact of that. That's an accurate depiction of the cut-out void inside the grip itself).

However, all of this does underline how uncertain my references are. I am sure I can get the final gun to look very close to the screen shots. But I am equally sure that the first prototype is going to involve at least some filing and sanding (and translating corrections back to the original CAD files.)

It's also not cheap. The top part is a slab of aluminium a full inch deep. A nice working size from Online Metals comes out to thirty bucks. So adding the stock for the rest of it, brass tubes and al, over a hundred bucks of metal and hardware. Then add the cost of how many end mills I may be destroying in order to cut that much.

On the other hand, an all-metal PPG is currently selling for over $900. So I think I can probably do this economically enough to be worthwhile.

Tuesday, September 30, 2014

Maybe I should get some bitcoins now

I have $56 credit in my Renderosity store, $19 credit in my Shapeways store, and $144 in my PayPal account courtesy of M40 grenade sales at the RPF. But I also just dropped $50 at Amazon for Pachmyers and a bottle of gun blue.

At some point I need to put some bucks down for a couple of larger chunks of aluminium. Slabs for the Jubal Early. And a big chunk of cylinder if I get the go-ahead to lathe up the flash hider for a Commando Cody.

I haven't entirely given up on the KP/-31; if I can just grind enough slag off the lugs to where they will function again, it might just be possible to make the welding alternative work. Especially since I discovered I have access to a wire welder (one of the el cheapo boxes, without even the external reels and gas fitting).

At some point I need to put some bucks down for a couple of larger chunks of aluminium. Slabs for the Jubal Early. And a big chunk of cylinder if I get the go-ahead to lathe up the flash hider for a Commando Cody.

I haven't entirely given up on the KP/-31; if I can just grind enough slag off the lugs to where they will function again, it might just be possible to make the welding alternative work. Especially since I discovered I have access to a wire welder (one of the el cheapo boxes, without even the external reels and gas fitting).

Wednesday, September 24, 2014

Successful Failure

I went in to Tech Shop today in an effort to determine if grinding and welding is an efficient way to proceed on the KP/-31 rebuild.

The effort was successful. I determined it is not.

Grinding and filing was tedious, the results marginal, and it would probably tech less time to machine new parts from scratch. Casting is looking better and better as an option.

The effort was successful. I determined it is not.

Grinding and filing was tedious, the results marginal, and it would probably tech less time to machine new parts from scratch. Casting is looking better and better as an option.

Saturday, September 6, 2014

Falcon to Eagle to Pigeons

I may have to back-burner my Tomb Raider fanfic "Day of the Falcon." (Falcons so far; Horus, the falcon-headed Egyptian god, the Tribute of the Falcon of the Knights of Malta, and a rival tomb raider calling himself Juan Carlos "el" Halcon...)

I'm trying to throw together the 0.5 version of the Duck Light, despite funds being tight for ordering parts. Started laying out the PCB in Fritzing, which may actually work for my needs, but I've been meaning to learn the free version of EagleCAD. Oh, yeah -- and there's a nice-looking open-source freeware option called KiCad that is worth checking out.

In re learning software packages, I still haven't gotten facile with Blender, which means I'm starting work on the Jubal Early with Carrara. Sigh. I've been introduced to the slicing and tool path tools I need to turn it into g-code the CNC milling machine can use, but that's going to be a learning curve as well.

I'm very worried I won't have enough time to properly repair microphones before I have to start Feeding the Birds -- aka mixing Mary Poppins. And I'm renting out my own gear over the same time period, which at least will relieve some of the financial stress.

And the KP/-31 receiver is still sitting on my desk. Which isn't bird-related at all, sorry. I read through a thread at a gunsmithing forum and that just underlined how many operations there are to machine the thing from scratch. 3d printing would also be expensive, and the shapes are wrong for CNC milling (not all in one piece, anyhow). Very possibly making a master model and casting that would be the most efficient, despite my worries about the strength of the result.

So I'm looking again at welding. I'll take a grinder to the parts and see how that goes first...

I'm trying to throw together the 0.5 version of the Duck Light, despite funds being tight for ordering parts. Started laying out the PCB in Fritzing, which may actually work for my needs, but I've been meaning to learn the free version of EagleCAD. Oh, yeah -- and there's a nice-looking open-source freeware option called KiCad that is worth checking out.

In re learning software packages, I still haven't gotten facile with Blender, which means I'm starting work on the Jubal Early with Carrara. Sigh. I've been introduced to the slicing and tool path tools I need to turn it into g-code the CNC milling machine can use, but that's going to be a learning curve as well.

I'm very worried I won't have enough time to properly repair microphones before I have to start Feeding the Birds -- aka mixing Mary Poppins. And I'm renting out my own gear over the same time period, which at least will relieve some of the financial stress.

And the KP/-31 receiver is still sitting on my desk. Which isn't bird-related at all, sorry. I read through a thread at a gunsmithing forum and that just underlined how many operations there are to machine the thing from scratch. 3d printing would also be expensive, and the shapes are wrong for CNC milling (not all in one piece, anyhow). Very possibly making a master model and casting that would be the most efficient, despite my worries about the strength of the result.

So I'm looking again at welding. I'll take a grinder to the parts and see how that goes first...

Labels:

BlinkM,

electronics,

fanfic,

LED,

machining,

props,

software,

suomi,

Tomb Raider

Subscribe to:

Comments (Atom)