And now the Maker Faire rant.

Bay Area Maker Faire (this weekend in San Mateo) was hot and crowded. Neither are the fault of Make or anyone else. To a certain extent "crowded" is a feature; it means tickets were sold, and Make is having trouble financing the Faire already. The heat is by itself not a problem, but combined with crowds you get a lack of access to shade and water that makes the Faire more difficult to endure (especially for those of us who are getting a little older -- or for the many who are bringing little children.)

And it is a given that economics drives the event. Sales (and booth rentals) are what covers the costs. But sales pushes the Faire to be about presentation. And, as with so many things, offering distraction for kids to bring in those parental dollars gradually takes over from any other goal. Maker Faire always had an element of spectacle and an element of hucksterism, but the desire to attract crowds and to have something to offer that will cause parents to bring children means these are eclipsing other aspects.

Aspects like sharing, education, information, trading, and networking.

The rest of the rant/Open Letter below the fold:

Tricks of the trade, discussion of design principles, and musings and rants about theater from a working theater technician/designer.

Showing posts with label geek. Show all posts

Showing posts with label geek. Show all posts

Sunday, May 21, 2017

Thursday, June 16, 2016

Crisis (on) Infinite Tombs

If you got the joke above, you are too much of a geek to need the explanation following.

Still hopeful to have a prototype new-model Holocron up by the end of the month. I revamped the shell design again and I really, really like the "stolen" design (aka, design inspired by one of the few holocrons to actually appear in a film or animation). I cringe to think of how much time I wasted trying to get other shell designs to work properly, when I should have just gone straight to doing this one right.

But work is tiring this week. Maybe a mistake listening to fan covers of game music instead of the history podcasts I usually listen to while I'm sanding wood and sorting scrap. Means I have more CPU cycles spare to dream up more ideas I don't have the time and energy to implement.

Such as: it would be a fun challenge to try to create the title track to a Tomb Raider game that never was.

Hence the reference above to DC Comic's famously flawed attempt to sort out their canon. There are essentially four unique Tomb Raider canon. Start with Core Design. In 1996, this game company released Tomb Raider. They followed it up with five more games, with 2003 seeing release of the polarizing Angel of Darkness. But in the end the sales figures, and some behind-the-scenes creative differences, sounded the end of that sequence.

Already there are two phantom games here; Core Design saw Angel of Darkness as the first of a tightly connected trilogy. In any case, although the earlier games in particular are rather casual towards any attempt at establishing an internal canon, as the games progressed they became progressively tighter-woven.

In the meantime the two movies with Angelina Jolie came and went. Core Design and Eidos (the parent company) thought the movie tie-in would help flagging sales but alas, neither property did as well as hoped. The two movies are consistent to each other, but have sharp differences with any other Tomb Raider canon.

(It is, of course, more...complex...than that. Winston has been a constant in every game but in the movie was replaced by Hillary. Yet, the Abingdon Estate of the movie became, quite clearly, the model for the manor in the Crystal Dynamics games. And so on and so forth.)

Crystal Dynamics took over, but gave some appearance of floundering with three games of markedly different character. Legend was the first, with a cheesy title sequence and more emphasis on the action-adventure aspects. Then Anniversary, which was a remake of Tomb Raider I...Natla, the T-rex, and all. Their third offering, Underworld, surprised everyone by making both previous games canonical with each other, and tying elements of both together into a single overarching plot.

Leaving aside a parallel Game Boy title as insufficiently memorable, 2010 also saw a new console set of top-down, cooperative-play games that appear to generally agree with the Crystal Dynamics trilogy. There had also been a comic book and a few books of debatable quality.

Finally, there is the 2013 game by Crystal Dynamics. This was the first time the series saw a complete reboot, a fully conscious and intentional change to the character and her back story and the style of the games. This is a darker and more psychological turn; the confident, independently wealthy adventuress who crosses the world with twin pistols blazing is replaced by a shy young archaeologist who has to find her inner strength after a shipwreck on a rather nasty little island.

Tomb Raider (2013) was followed by Rise of the Tomb Raider and a licensed comic book kept carefully within the framework established by the company. There are also plans for at least one movie; this marks the first time the series has clearly established a canon -- a brand, really -- and made sure all available materials stay in agreement with it.

So, right. A lot of background there. My idea, such as it was, is that there was a fourth Crystal Dynamics game building on what they had done before. I'm calling it Tomb Raider: Legacy. Fresh from the events of Underworld, Lara has at last achieved closure after her encounter with the remains of her vanished mother in the Norse underworld. She has returned home to the ruins of Croft Manor.

But it turns out another figure from her past is not as dead as everyone thought. Werner von Croy, her one-time mentor, and time has not mellowed him in the least. He is as dangerously obsessed as ever, and he leads her into discovery (in the usual exotic locales, particularly the Giza Plateau, the Bolivian jungle where her father vanished, and much nearer home; Stonehenge) of some particularly dark secrets of her own family. And betrayal is sure to follow.

Just like with Anniversary and Underworld, this game would have brought elements from some of the first games -- particularly Tomb Raider: The Last Revelation -- back into canon. It also would both reproduce the "Teen Lara" section from Legend and the legendary Revelation tutorial level by having you play as Von Croy's young student.

This is yet another direction, as the game would be deeper psychologically, generally slower and rather more role-playing in style; like Angel of Darkness you'd spend a lot of your time above ground in the everyday world interacting with people.

And Troels Brun Folmann is back again for the musical chores. This is an orchestral score like Underworld but with a lighter touch; more of a chamber orchestra sound, with the ethnic instruments of Legend -- except in this case, often referencing English folk music.

Every Tomb Raider game has had a unique theme, but usually close to or otherwise audibly referencing the original haunting melody Nathan McCree composed for solo oboe. A large part of the fun of this project would be to see if I can develop a theme and treatment that seats itself within the real history of the scoring for this franchise.

So I actually turned on the Behringer this evening and spent a few minutes trying to work the kinks out of my hands. I've never been even a "good" keyboard player -- on my best day I might achieve "passable," and I'm rusty now. But it does seem to still be there.

Maybe once the holocron is finished I'll have some more time to play....

Still hopeful to have a prototype new-model Holocron up by the end of the month. I revamped the shell design again and I really, really like the "stolen" design (aka, design inspired by one of the few holocrons to actually appear in a film or animation). I cringe to think of how much time I wasted trying to get other shell designs to work properly, when I should have just gone straight to doing this one right.

But work is tiring this week. Maybe a mistake listening to fan covers of game music instead of the history podcasts I usually listen to while I'm sanding wood and sorting scrap. Means I have more CPU cycles spare to dream up more ideas I don't have the time and energy to implement.

Such as: it would be a fun challenge to try to create the title track to a Tomb Raider game that never was.

Hence the reference above to DC Comic's famously flawed attempt to sort out their canon. There are essentially four unique Tomb Raider canon. Start with Core Design. In 1996, this game company released Tomb Raider. They followed it up with five more games, with 2003 seeing release of the polarizing Angel of Darkness. But in the end the sales figures, and some behind-the-scenes creative differences, sounded the end of that sequence.

Already there are two phantom games here; Core Design saw Angel of Darkness as the first of a tightly connected trilogy. In any case, although the earlier games in particular are rather casual towards any attempt at establishing an internal canon, as the games progressed they became progressively tighter-woven.

In the meantime the two movies with Angelina Jolie came and went. Core Design and Eidos (the parent company) thought the movie tie-in would help flagging sales but alas, neither property did as well as hoped. The two movies are consistent to each other, but have sharp differences with any other Tomb Raider canon.

(It is, of course, more...complex...than that. Winston has been a constant in every game but in the movie was replaced by Hillary. Yet, the Abingdon Estate of the movie became, quite clearly, the model for the manor in the Crystal Dynamics games. And so on and so forth.)

Crystal Dynamics took over, but gave some appearance of floundering with three games of markedly different character. Legend was the first, with a cheesy title sequence and more emphasis on the action-adventure aspects. Then Anniversary, which was a remake of Tomb Raider I...Natla, the T-rex, and all. Their third offering, Underworld, surprised everyone by making both previous games canonical with each other, and tying elements of both together into a single overarching plot.

Leaving aside a parallel Game Boy title as insufficiently memorable, 2010 also saw a new console set of top-down, cooperative-play games that appear to generally agree with the Crystal Dynamics trilogy. There had also been a comic book and a few books of debatable quality.

Finally, there is the 2013 game by Crystal Dynamics. This was the first time the series saw a complete reboot, a fully conscious and intentional change to the character and her back story and the style of the games. This is a darker and more psychological turn; the confident, independently wealthy adventuress who crosses the world with twin pistols blazing is replaced by a shy young archaeologist who has to find her inner strength after a shipwreck on a rather nasty little island.

Tomb Raider (2013) was followed by Rise of the Tomb Raider and a licensed comic book kept carefully within the framework established by the company. There are also plans for at least one movie; this marks the first time the series has clearly established a canon -- a brand, really -- and made sure all available materials stay in agreement with it.

So, right. A lot of background there. My idea, such as it was, is that there was a fourth Crystal Dynamics game building on what they had done before. I'm calling it Tomb Raider: Legacy. Fresh from the events of Underworld, Lara has at last achieved closure after her encounter with the remains of her vanished mother in the Norse underworld. She has returned home to the ruins of Croft Manor.

But it turns out another figure from her past is not as dead as everyone thought. Werner von Croy, her one-time mentor, and time has not mellowed him in the least. He is as dangerously obsessed as ever, and he leads her into discovery (in the usual exotic locales, particularly the Giza Plateau, the Bolivian jungle where her father vanished, and much nearer home; Stonehenge) of some particularly dark secrets of her own family. And betrayal is sure to follow.

Just like with Anniversary and Underworld, this game would have brought elements from some of the first games -- particularly Tomb Raider: The Last Revelation -- back into canon. It also would both reproduce the "Teen Lara" section from Legend and the legendary Revelation tutorial level by having you play as Von Croy's young student.

This is yet another direction, as the game would be deeper psychologically, generally slower and rather more role-playing in style; like Angel of Darkness you'd spend a lot of your time above ground in the everyday world interacting with people.

And Troels Brun Folmann is back again for the musical chores. This is an orchestral score like Underworld but with a lighter touch; more of a chamber orchestra sound, with the ethnic instruments of Legend -- except in this case, often referencing English folk music.

Every Tomb Raider game has had a unique theme, but usually close to or otherwise audibly referencing the original haunting melody Nathan McCree composed for solo oboe. A large part of the fun of this project would be to see if I can develop a theme and treatment that seats itself within the real history of the scoring for this franchise.

So I actually turned on the Behringer this evening and spent a few minutes trying to work the kinks out of my hands. I've never been even a "good" keyboard player -- on my best day I might achieve "passable," and I'm rusty now. But it does seem to still be there.

Maybe once the holocron is finished I'll have some more time to play....

Sunday, June 12, 2016

Rudimentary what?

If a lathe can build a lathe, it makes total sense that there are scads of people upgrading their cheap T962 reflow ovens (used to solder surface mount components)....with new circuit boards filled with surface mount components. (Well, the first thing I printed with a borrowed M3D 3d printer was a spool holder for itself).

I'm already unhappy with some aspects of my new board. I plan to drop down to 0805 chip size, for instance, and (having carefully read the Design Rules at OSHPark) narrower traces packed closer together. I can probably shrink the board by half! But I'll wait before I change anything. I expect to learn quite a bit when I solder up the first prototypes, and more when I try to program them and put them in Holocron kits.

Already I have grand dreams, of course. Given one of various audio chips and a socket for micro-SD, I could actually make a "talking" holocron. And of course if some of the ideas on the new board pan out, I'll be one step closer to actually having the DuckLite marketable. Oh, yes. And back to Wraith Stone as well (already I'm wondering...can I do capacitive touch sensing if it is hung around my neck?)

Also burned a CD for dad. He probably knows very well that video games passed the chip-tunes barrier roughly the time they stopped using vector graphics. But I'm not putting together a "greatest hits." The original conversation was about amateur covers, so I've tried to pack in a good spectrum of skill levels and a variety of approaches, from people recording themselves on a camera phone messing around on the piano in their front room, to professional-level production numbers like the work of Lindsey Stirling.

The first video I saw from Lindsey, she did a nice cover on violin of themes from the Zelda series. The production values really raised the bar; exceptional recording and mixing and professional-level backing tracks that are almost seamless. And the video is of her traipsing in gorgeous scenery, with her violin and with equally gorgeous outfits based on characters from the game. But what really nails it is how lively she is, sawing away at her violin, leaping about, all with this fantastic grin on her face.

Oh, yes, and there was one of those Oh My God moments. You know how it is when you've just learned about something new, something you are just getting into, something you want to share your excitement of with friends? And you open the wrong door and suddenly there's this massive conference room absolutely jammed by people who are into the same thing and know it more deeply and more expertly and are more passionate about it than you will ever be.

Yeah, all of this discovery of amateur covers of music from video games has been like that. Well, I knew they were out there. I didn't realize just how many, how good they really were, and how popular they are. The moment that really informed me was a video from a concert of game music (with a professional orchestra and band) at the Symphony Hall in Boston.

So soloist steps up and starts singing. Giant cheer as the crowd recognizes the number ("Still Alive," of course, from the breakout hit Portal). But that's not the worst. They start singing along. A huge, symphony-hall sized audience, and every one was a better fan than I'll ever be. I recognize the tune. They know all the words.

(There's another moment in the same video that perhaps needs some setting up. The lyric is "Maybe Black Mesa? That was a joke, haha, fat chance." Well, the soloist stepped back and let the audience sing that part. And I can't help thinking that there was a certain bitter humor in their voices. Because "Black Mesa" is the location of the first game in the Half-Life series, games created by the same company who made Portal, and the long-awaited third and final game of that series is now considered by fans to be the gaming industry's greatest piece of vaporware. "Haha, fat chance," all right. There is no longer a "maybe" about Black Mesa.)

So anyhow. Tried to select a number of piano covers, and made a conscious effort to bring back some of the same themes (in the way a concerto might) by showing off different covers of material from the same games. And I tried to focus in on games I've played myself but not only aren't there a lot of offerings there but that would leave off some of the great stuff like Skyrim, the Final Fantasy series, and of course Zelda. And I shuffled and shuffled to get a good flow, building up tension and relieving it, contrasting styles while maintaining certain continuities to help one track follow another.

Tried, too, to include some of the contexting. To show the penetration of game music into church choirs and high school marching bands, the intense fan interest, the stature of acoustic instruments and vocalists and life performance and the cross-cultural world community (as contrast the possible stereotype of nerdy white guys tinkering up music tracks in MIDI). And show too the social networking, the recording and collaboration and jam sessions that take place through the online world.

What I really wish is a little more space than a CD. I have five hours of the stuff already on my hard disk (I auditioned twice that many before making even that selection, and that's barely a quarter of what turned up in my rather basic searches). But then, dad will probably turn off around the middle of the second track anyhow.

So now I just need to find the Ukulele music I promised...

I'm already unhappy with some aspects of my new board. I plan to drop down to 0805 chip size, for instance, and (having carefully read the Design Rules at OSHPark) narrower traces packed closer together. I can probably shrink the board by half! But I'll wait before I change anything. I expect to learn quite a bit when I solder up the first prototypes, and more when I try to program them and put them in Holocron kits.

Already I have grand dreams, of course. Given one of various audio chips and a socket for micro-SD, I could actually make a "talking" holocron. And of course if some of the ideas on the new board pan out, I'll be one step closer to actually having the DuckLite marketable. Oh, yes. And back to Wraith Stone as well (already I'm wondering...can I do capacitive touch sensing if it is hung around my neck?)

Also burned a CD for dad. He probably knows very well that video games passed the chip-tunes barrier roughly the time they stopped using vector graphics. But I'm not putting together a "greatest hits." The original conversation was about amateur covers, so I've tried to pack in a good spectrum of skill levels and a variety of approaches, from people recording themselves on a camera phone messing around on the piano in their front room, to professional-level production numbers like the work of Lindsey Stirling.

The first video I saw from Lindsey, she did a nice cover on violin of themes from the Zelda series. The production values really raised the bar; exceptional recording and mixing and professional-level backing tracks that are almost seamless. And the video is of her traipsing in gorgeous scenery, with her violin and with equally gorgeous outfits based on characters from the game. But what really nails it is how lively she is, sawing away at her violin, leaping about, all with this fantastic grin on her face.

Oh, yes, and there was one of those Oh My God moments. You know how it is when you've just learned about something new, something you are just getting into, something you want to share your excitement of with friends? And you open the wrong door and suddenly there's this massive conference room absolutely jammed by people who are into the same thing and know it more deeply and more expertly and are more passionate about it than you will ever be.

Yeah, all of this discovery of amateur covers of music from video games has been like that. Well, I knew they were out there. I didn't realize just how many, how good they really were, and how popular they are. The moment that really informed me was a video from a concert of game music (with a professional orchestra and band) at the Symphony Hall in Boston.

So soloist steps up and starts singing. Giant cheer as the crowd recognizes the number ("Still Alive," of course, from the breakout hit Portal). But that's not the worst. They start singing along. A huge, symphony-hall sized audience, and every one was a better fan than I'll ever be. I recognize the tune. They know all the words.

(There's another moment in the same video that perhaps needs some setting up. The lyric is "Maybe Black Mesa? That was a joke, haha, fat chance." Well, the soloist stepped back and let the audience sing that part. And I can't help thinking that there was a certain bitter humor in their voices. Because "Black Mesa" is the location of the first game in the Half-Life series, games created by the same company who made Portal, and the long-awaited third and final game of that series is now considered by fans to be the gaming industry's greatest piece of vaporware. "Haha, fat chance," all right. There is no longer a "maybe" about Black Mesa.)

So anyhow. Tried to select a number of piano covers, and made a conscious effort to bring back some of the same themes (in the way a concerto might) by showing off different covers of material from the same games. And I tried to focus in on games I've played myself but not only aren't there a lot of offerings there but that would leave off some of the great stuff like Skyrim, the Final Fantasy series, and of course Zelda. And I shuffled and shuffled to get a good flow, building up tension and relieving it, contrasting styles while maintaining certain continuities to help one track follow another.

Tried, too, to include some of the contexting. To show the penetration of game music into church choirs and high school marching bands, the intense fan interest, the stature of acoustic instruments and vocalists and life performance and the cross-cultural world community (as contrast the possible stereotype of nerdy white guys tinkering up music tracks in MIDI). And show too the social networking, the recording and collaboration and jam sessions that take place through the online world.

What I really wish is a little more space than a CD. I have five hours of the stuff already on my hard disk (I auditioned twice that many before making even that selection, and that's barely a quarter of what turned up in my rather basic searches). But then, dad will probably turn off around the middle of the second track anyhow.

So now I just need to find the Ukulele music I promised...

Saturday, August 2, 2014

Drum party in the tomb

Random thoughts over the (loooooong) closing weekend.

We had another sub in the pit, and a couple of technical issues, and this underlines: there is something systemically wrong about how music is done in music theater. Our Music Director calls it a problem of musician culture.

Musicians are called for a "service," which works out to pretty much the length of a performance, plus whatever bare minimum to get their butts into their seats and unpack their instruments. This is why it took three weeks to get the musical to start sounding like a musical instead of a bunch of uncoordinated noises. There's no time; no time for rehearsal, no time for brush-up or warm-up, no time for sound check -- not even enough time for notes. I don't even see the orchestra until five minutes before the house is opened. It took us two days just to add a ukulele to the pit, and it would have taken a week more to get it integrated into the score.

With these sorts of time constraints, reinforcing a pit orchestra is not like sound check for a band. It is more like working at an open mic. The band walks in and they start playing, and if the mics and monitors aren't right, then oh well. And the audience suffers along with everyone else, because there's no time available to fix it. Not in tech, and not during the run.

Drummers. I think I know where our current drummer is. He's got a good balance when he tries; between the different elements of his kit, and between him and the rest of the band. But I think he is feeling constrained, if not put upon, while doing this. It isn't easy to play with control and play softly, not without practice, and since most music directors have simply given up on even asking they don't get that practice.

(After many, many poor experiences, I don't bother telling drummers they are too loud. Telling them never fixes it, and often makes things worse).

So since this is unnatural (in his mind) he's welcomes the moments -- louder songs -- where (again, in his mind, and only in his mind) he can relax and play the way he is used to.

Which sounds like shit, by the way. Not just too loud for the mix, and too loud for the space, but poorly balanced internally. His cymbals overwhelm everything else, and don't even sound like they are in time. So it is just a wash of white noise with very little musical content, and practically none of the good tone his kit has available.

I suspect to him, these are the moment when he is actually "allowed to play drums" and the rest of the show, he is putting up with something he considers wrong and awkward because he doesn't want to lose the gig.

Which means there is no hope in hell of him internalizing the necessary lesson, and no point in anyone trying to educate him. And the pity is, over three quarters of the drummers out there get the same free ride borne of the people around them just plain giving up. Leaving only a few rare ones who see themselves as members of a band.

(I really, really expected him to cut loose on closing night, because I've had that happen before. He didn't. Oh, he came up a little overall, but he was already playing close to peak in other moments, so the impact wasn't bad. And I made it a point to break my rule and thank him after the show for not going there as so many have before.)

Another cast get-together at night, at a noisy ice-cream place. And, sure, I'm missing the networking by being there. People hire people they know. Having your face out there, being seen out at the parties and opening nights and so forth, that's a job skill. But it is one I'm poor at, and I suspect a lot of techies are poor at.

Because conversation in a crowded room is a specific skill. It requires wit. You need to be able to adjust quickly, think on the fly. It is social skills, not language skills. And techies don't cultivate grooming skills. They cultivate knowledge, and knowledge can't be communicated in tweets. When techies size each other up, it isn't done with a couple of words and looking each other in the eye. It is done with a flurry of challenges and concepts and thought problems. Techies socialize over blueprints.

Different skill set. Different interests. Different comfort level. I should probably still do it, but there's an equal chance all I'd communicate to possible employers is, "Uncomfortable around others." If not an absolute bore (the kind of talk a techie likes, is the kind of talk that at a party is the guy who corners you to talk about their bird feeder for twenty minutes.)

Yes, I'm ragging on Tomb Raider 2013. And, yes, I'm in a sister industry and I understand how a lot of design decisions are not carefully weighted, carefully discussed, deliberately taken options. I understand how history can weigh on a project ("This isn't right, but we spent half our budget on it and there's not enough time before opening to re-do it.") And similar sorts of extraneous and often invisible forces that caused certain choices to be made.

I've also studied enough game design (was a Gamasutra member, read the trade mags for a year or two, and a handful of books on design as well) to understand there are subtle trade-offs being made. And, yes, what I think I'd want to play, may not be what the good and careful marketing research and playtest groups showed is what the larger customer base wants to play.

That said, more ragging.

I've been doing some skulking on my "Role Playing" pass through the game. The one where I try not to game it, but try to react as I think Lara should be reacting at every moment. Which includes running pell-mell into tight situations when Sam is in immediate danger, rather than take proper care.

But anyhow. I've been making an effort to bypass, or to talk to, the random encounters with smaller groups of Solarii. I've also been listening to their conversations more. I've yet to find a group I can actually bypass completely. The developer who said you aren't forced to fight them -- he was a total liar. They WILL spot you, and if you try to run past, they will shoot you right off your zip line.

And as for listening...

It's great that they have all these little stories. I can't fault the variety of the NPCs, especially given that they are specifically a limited selection pool; fit and physically tough, amoral and brutal men who were picked out by Mathias (and could survive his selection process). There is a surprising variety in voices and models despite this.

However. About half of the conversations end with them moving to where they have you in sight, if not surrounded. If you insist on listening to the entire conversation, you are much more likely to get killed. Once again, the gameplay is at odds with the story-telling. From a story-telling point of view, what they have to say is important. From a gaming point of view, you should kill them the moment they are in range.

We had another sub in the pit, and a couple of technical issues, and this underlines: there is something systemically wrong about how music is done in music theater. Our Music Director calls it a problem of musician culture.

Musicians are called for a "service," which works out to pretty much the length of a performance, plus whatever bare minimum to get their butts into their seats and unpack their instruments. This is why it took three weeks to get the musical to start sounding like a musical instead of a bunch of uncoordinated noises. There's no time; no time for rehearsal, no time for brush-up or warm-up, no time for sound check -- not even enough time for notes. I don't even see the orchestra until five minutes before the house is opened. It took us two days just to add a ukulele to the pit, and it would have taken a week more to get it integrated into the score.

With these sorts of time constraints, reinforcing a pit orchestra is not like sound check for a band. It is more like working at an open mic. The band walks in and they start playing, and if the mics and monitors aren't right, then oh well. And the audience suffers along with everyone else, because there's no time available to fix it. Not in tech, and not during the run.

Drummers. I think I know where our current drummer is. He's got a good balance when he tries; between the different elements of his kit, and between him and the rest of the band. But I think he is feeling constrained, if not put upon, while doing this. It isn't easy to play with control and play softly, not without practice, and since most music directors have simply given up on even asking they don't get that practice.

(After many, many poor experiences, I don't bother telling drummers they are too loud. Telling them never fixes it, and often makes things worse).

So since this is unnatural (in his mind) he's welcomes the moments -- louder songs -- where (again, in his mind, and only in his mind) he can relax and play the way he is used to.

Which sounds like shit, by the way. Not just too loud for the mix, and too loud for the space, but poorly balanced internally. His cymbals overwhelm everything else, and don't even sound like they are in time. So it is just a wash of white noise with very little musical content, and practically none of the good tone his kit has available.

I suspect to him, these are the moment when he is actually "allowed to play drums" and the rest of the show, he is putting up with something he considers wrong and awkward because he doesn't want to lose the gig.

Which means there is no hope in hell of him internalizing the necessary lesson, and no point in anyone trying to educate him. And the pity is, over three quarters of the drummers out there get the same free ride borne of the people around them just plain giving up. Leaving only a few rare ones who see themselves as members of a band.

(I really, really expected him to cut loose on closing night, because I've had that happen before. He didn't. Oh, he came up a little overall, but he was already playing close to peak in other moments, so the impact wasn't bad. And I made it a point to break my rule and thank him after the show for not going there as so many have before.)

Another cast get-together at night, at a noisy ice-cream place. And, sure, I'm missing the networking by being there. People hire people they know. Having your face out there, being seen out at the parties and opening nights and so forth, that's a job skill. But it is one I'm poor at, and I suspect a lot of techies are poor at.

Because conversation in a crowded room is a specific skill. It requires wit. You need to be able to adjust quickly, think on the fly. It is social skills, not language skills. And techies don't cultivate grooming skills. They cultivate knowledge, and knowledge can't be communicated in tweets. When techies size each other up, it isn't done with a couple of words and looking each other in the eye. It is done with a flurry of challenges and concepts and thought problems. Techies socialize over blueprints.

Different skill set. Different interests. Different comfort level. I should probably still do it, but there's an equal chance all I'd communicate to possible employers is, "Uncomfortable around others." If not an absolute bore (the kind of talk a techie likes, is the kind of talk that at a party is the guy who corners you to talk about their bird feeder for twenty minutes.)

Yes, I'm ragging on Tomb Raider 2013. And, yes, I'm in a sister industry and I understand how a lot of design decisions are not carefully weighted, carefully discussed, deliberately taken options. I understand how history can weigh on a project ("This isn't right, but we spent half our budget on it and there's not enough time before opening to re-do it.") And similar sorts of extraneous and often invisible forces that caused certain choices to be made.

I've also studied enough game design (was a Gamasutra member, read the trade mags for a year or two, and a handful of books on design as well) to understand there are subtle trade-offs being made. And, yes, what I think I'd want to play, may not be what the good and careful marketing research and playtest groups showed is what the larger customer base wants to play.

That said, more ragging.

I've been doing some skulking on my "Role Playing" pass through the game. The one where I try not to game it, but try to react as I think Lara should be reacting at every moment. Which includes running pell-mell into tight situations when Sam is in immediate danger, rather than take proper care.

But anyhow. I've been making an effort to bypass, or to talk to, the random encounters with smaller groups of Solarii. I've also been listening to their conversations more. I've yet to find a group I can actually bypass completely. The developer who said you aren't forced to fight them -- he was a total liar. They WILL spot you, and if you try to run past, they will shoot you right off your zip line.

And as for listening...

It's great that they have all these little stories. I can't fault the variety of the NPCs, especially given that they are specifically a limited selection pool; fit and physically tough, amoral and brutal men who were picked out by Mathias (and could survive his selection process). There is a surprising variety in voices and models despite this.

However. About half of the conversations end with them moving to where they have you in sight, if not surrounded. If you insist on listening to the entire conversation, you are much more likely to get killed. Once again, the gameplay is at odds with the story-telling. From a story-telling point of view, what they have to say is important. From a gaming point of view, you should kill them the moment they are in range.

Friday, June 6, 2014

The OTHER Kind of Theater Person

I was just reading the rehearsal notes from last night and, yeah, sometimes it bugs me that I don't know all these theater references (and pop culture references). I've never seen a show on Broadway (or the West End) -- heck, I've only seen a show at the Curran once or twice. I don't follow the Oscars, or the careers of famous actors or designers. I don't have the slightest what is being written today, unless I happen to get hired to work it.

And sure, some of that is just not being that interested. But it is also that there are only so many career-related hours in the day. To work technical theater, I have to spend at least an hour every day studying the ever-evolving technology map, plus constantly improving my understanding of acoustics, psycho-acoustics, music theory, electronics, information theory, etc., etc.

But the divide is of course more basic. You could see it back in high school; the techies would be the small group in the back of the cast party, still wearing crew blacks and not talking to anyone else.

Actors are generally in for a longer haul but with a smaller time commitment per interval. This means they need to be networking through the rehearsal process (and can often take on multiple simultaneous commitments). Techs and designers are on for a shorter haul with longer days. Every hour spent in tech rehearsal is a second hour of work that needs to be done before opening. For me, at least, that means I don't network during a job, or do anything other than work and sleep (and not a lot of the later, either).

Which is a good fit to what seems the archetypal character; actors are social, egregious, popular -- and they know the mainstream culture well. Techies are loners, outcasts, and geeks -- and what they know is technology.

The Venn diagram has intersect, but between the norm of each group there is no meeting of minds.

And sure, some of that is just not being that interested. But it is also that there are only so many career-related hours in the day. To work technical theater, I have to spend at least an hour every day studying the ever-evolving technology map, plus constantly improving my understanding of acoustics, psycho-acoustics, music theory, electronics, information theory, etc., etc.

But the divide is of course more basic. You could see it back in high school; the techies would be the small group in the back of the cast party, still wearing crew blacks and not talking to anyone else.

Actors are generally in for a longer haul but with a smaller time commitment per interval. This means they need to be networking through the rehearsal process (and can often take on multiple simultaneous commitments). Techs and designers are on for a shorter haul with longer days. Every hour spent in tech rehearsal is a second hour of work that needs to be done before opening. For me, at least, that means I don't network during a job, or do anything other than work and sleep (and not a lot of the later, either).

Which is a good fit to what seems the archetypal character; actors are social, egregious, popular -- and they know the mainstream culture well. Techies are loners, outcasts, and geeks -- and what they know is technology.

The Venn diagram has intersect, but between the norm of each group there is no meeting of minds.

Wednesday, August 14, 2013

The Geek Cred Check

Yes, it happens. Male geeks do it to each other constantly. It's part of the fun (for at least some of us.) The problem is when it is used to be exclusionary.

And I think this is a venue thing. Makers Faire? Not cool. It doesn't matter if the person you are talking to has never held a soldering iron or a Dremel, or is Harrison Krix. Don't do it. Don't exclude. Don't assume. Don't talk down.

Same thing for anyone -- for everyone -- at a convention, be it Dungeons and Dragons, Comic Books, or whatever. They paid the price at the door, they made time on their weekend to come out? Then they are part of the club. That is what that venue is there for. It is for everyone to enjoy, regardless of whether they can name more than one Green Lantern.

But way off in another corner, there is tech. It is one thing if you are sizing up someone just because they happened to mention Arduino in a social setting. But it is another thing entirely if you are working, and the quality of the show may depend on that person actually knowing what it is they claim to know.

Every place I've done audio, or theatrical lighting, I've had to play the lock antlers game. I've been the one defending myself just as often as I've been the instigator, too (I tend towards a lighter touch when I'm probing a co-worker's abilities.)

I need to say more here. I've been on a job more than once when a hotshot has tried to take over, shunt me aside with a, "Since you obviously don't have the l33t tech skillz I do, we're going to do it my way." And that's when I go into full riposte, pulling up tech specs and factinos and, if I have to, cutting them off at the knees in the process.

And, yeah, my ego is what causes this, but I also have a belief that I know my stuff and know what works in my theater, and it would be bad for the show for someone who is only trying to show off to go around changing what works, fixing what wasn't broke, and basically putting us in a place where we can't get the show up on time.

Especially when the antler game reveals a deep and entrenched Dunning-Kruger on the part of the person who is convinced the best thing to do is rip it all out (without even looking at what is already there) and start from scratch the "right" way.

And, yeah, this sort of locking antlers can be fun sometimes. I've done it over tech, over science, over the few SF or comic book properties I'm actually interested in (not that many, really). And even over history -- my best friend is a history buff with an incredible memory and I just HAVE to throw in a, "The world wonders?" every now and then just to show I'm active in the conversation.

As I'm thinking about it, I think part of the deal is that geek cred in a specific subject is not the same as having basic geek creds. It's like a one-point skill versus the 10 point all-skills. And the problem is, if you are a white straight guy who isn't too obviously into sports, you pretty much get the basic cred for free.

I can cheerfully admit I stopped reading Marvel just about when Power Pack moved to NY, and to me Jean Gray only came back once (as the Phoenix). I can ruefully admit I don't grasp object-oriented, and I only do a little bog-standard C. I can own up to never having hooked up a ribbon microphone, and having no time in a real studio. But none of those admissions make me not a credentialed geek. They just mean I don't get credentials in that specific genre.

And this wouldn't be the same if I were female, a person of color, or some other convenient "other." Where the assumption of geekitude isn't default, and I'd have to do the antler thing just to be accepted as having an expertise in something.

And then, of course, since the entire point of the exercise is exclusionary, sorting the us from the them, were I that "She's one of them fake geek girls!" person failing even one of the spot checks is counted as failing the entire exercise. As that pre-supposed other, I would not be allowed to shrug off a question with, "Never read DC, never got into MLP, but I know the Whoniverse up down and sideways."

And, you know, I'd like to think the tech and Maker communities are better than this. That we could instead embrace the diversity. "You don't solder, but you know how to sew? Hey...maybe I could learn something from you."

But it has to start with not doing the credential thing anywhere other than on the shop floor, where power tools are spinning (or on the grid when a show is opening in three hours).

Or, rather, not doing it in a, "Prove yourself to my standard or I'm going to kick you out of the club."

And I think this is a venue thing. Makers Faire? Not cool. It doesn't matter if the person you are talking to has never held a soldering iron or a Dremel, or is Harrison Krix. Don't do it. Don't exclude. Don't assume. Don't talk down.

Same thing for anyone -- for everyone -- at a convention, be it Dungeons and Dragons, Comic Books, or whatever. They paid the price at the door, they made time on their weekend to come out? Then they are part of the club. That is what that venue is there for. It is for everyone to enjoy, regardless of whether they can name more than one Green Lantern.

But way off in another corner, there is tech. It is one thing if you are sizing up someone just because they happened to mention Arduino in a social setting. But it is another thing entirely if you are working, and the quality of the show may depend on that person actually knowing what it is they claim to know.

Every place I've done audio, or theatrical lighting, I've had to play the lock antlers game. I've been the one defending myself just as often as I've been the instigator, too (I tend towards a lighter touch when I'm probing a co-worker's abilities.)

I need to say more here. I've been on a job more than once when a hotshot has tried to take over, shunt me aside with a, "Since you obviously don't have the l33t tech skillz I do, we're going to do it my way." And that's when I go into full riposte, pulling up tech specs and factinos and, if I have to, cutting them off at the knees in the process.

And, yeah, my ego is what causes this, but I also have a belief that I know my stuff and know what works in my theater, and it would be bad for the show for someone who is only trying to show off to go around changing what works, fixing what wasn't broke, and basically putting us in a place where we can't get the show up on time.

Especially when the antler game reveals a deep and entrenched Dunning-Kruger on the part of the person who is convinced the best thing to do is rip it all out (without even looking at what is already there) and start from scratch the "right" way.

And, yeah, this sort of locking antlers can be fun sometimes. I've done it over tech, over science, over the few SF or comic book properties I'm actually interested in (not that many, really). And even over history -- my best friend is a history buff with an incredible memory and I just HAVE to throw in a, "The world wonders?" every now and then just to show I'm active in the conversation.

As I'm thinking about it, I think part of the deal is that geek cred in a specific subject is not the same as having basic geek creds. It's like a one-point skill versus the 10 point all-skills. And the problem is, if you are a white straight guy who isn't too obviously into sports, you pretty much get the basic cred for free.

I can cheerfully admit I stopped reading Marvel just about when Power Pack moved to NY, and to me Jean Gray only came back once (as the Phoenix). I can ruefully admit I don't grasp object-oriented, and I only do a little bog-standard C. I can own up to never having hooked up a ribbon microphone, and having no time in a real studio. But none of those admissions make me not a credentialed geek. They just mean I don't get credentials in that specific genre.

And this wouldn't be the same if I were female, a person of color, or some other convenient "other." Where the assumption of geekitude isn't default, and I'd have to do the antler thing just to be accepted as having an expertise in something.

And then, of course, since the entire point of the exercise is exclusionary, sorting the us from the them, were I that "She's one of them fake geek girls!" person failing even one of the spot checks is counted as failing the entire exercise. As that pre-supposed other, I would not be allowed to shrug off a question with, "Never read DC, never got into MLP, but I know the Whoniverse up down and sideways."

And, you know, I'd like to think the tech and Maker communities are better than this. That we could instead embrace the diversity. "You don't solder, but you know how to sew? Hey...maybe I could learn something from you."

But it has to start with not doing the credential thing anywhere other than on the shop floor, where power tools are spinning (or on the grid when a show is opening in three hours).

Or, rather, not doing it in a, "Prove yourself to my standard or I'm going to kick you out of the club."

Tuesday, February 19, 2013

Back to Processing

I'm moving away from hardware MIDI.

9/10 of the time, the MIDI signals generated by my various gadgets are going into a laptop anyhow. And as I gain confidence in programming, I think it is easier to write client-side software than to try to do everything on the embedded processor of a black box.

This seems like it is going to be the form of my DuckNodes. On the Node end, LiPo battery and charge circuit, monitor/feedback LEDs, XBee. On the master end, Xbee node with FTDI adaptor plugged into a USB port -- and the rest is software.

Sure, I could dress up the receiver with some indicator blinkenlights. I'm also tempted to make it in the form of a Diesel-Punk USB stick. The first show I did using software at the receiver end, I stuck the receiver XBee inside a rubber ducky -- a yellow plastic bathtub duck -- to protect it.

(That's the actual hardware in the picture there; one Xbee inside the television remote, one inside the duck, with the latter connected by USB cable to the Processing sketch visible on the desktop.)

This is a bad time for me to be buying parts. So this will have to do to construct the prototype DuckNode; a Modern Devices accelerometer, XBee (not XBee Pro), and AAA batteries. I need to read up on the chip, though, to find out the voltage tolerance and so forth. But for the nonce I'm working on the software layer, and for that my XBee-equipped Easy Button is sufficient.

9/10 of the time, the MIDI signals generated by my various gadgets are going into a laptop anyhow. And as I gain confidence in programming, I think it is easier to write client-side software than to try to do everything on the embedded processor of a black box.

This seems like it is going to be the form of my DuckNodes. On the Node end, LiPo battery and charge circuit, monitor/feedback LEDs, XBee. On the master end, Xbee node with FTDI adaptor plugged into a USB port -- and the rest is software.

Sure, I could dress up the receiver with some indicator blinkenlights. I'm also tempted to make it in the form of a Diesel-Punk USB stick. The first show I did using software at the receiver end, I stuck the receiver XBee inside a rubber ducky -- a yellow plastic bathtub duck -- to protect it.

(That's the actual hardware in the picture there; one Xbee inside the television remote, one inside the duck, with the latter connected by USB cable to the Processing sketch visible on the desktop.)

This is a bad time for me to be buying parts. So this will have to do to construct the prototype DuckNode; a Modern Devices accelerometer, XBee (not XBee Pro), and AAA batteries. I need to read up on the chip, though, to find out the voltage tolerance and so forth. But for the nonce I'm working on the software layer, and for that my XBee-equipped Easy Button is sufficient.

Labels:

electronics,

geek,

MIDI,

Processing,

programming,

wireless,

XBee

Monday, July 30, 2012

Run, Robot

Consider this post a re-visit of my "Theater Should not be a Hackerspace" rant.

I'm in the middle of the run of a very complicated show that was thrown together too fast on too small a budget, by a company that has fallen in to a pattern of doing that. The props and effects, some of the costumes and set dressing, and other basic technical elements are held together with gaff tape and hot glue.

My robot is one of these elements. Although I spent the money and did the research for a robust chassis and control linkage, what we had time for is a $40 R/C car chassis carrying the lightest extruded-foam body I could build on top of it. Even a fiberglas shell would be too heavy for the undersized motor -- and at that, I had to tighten the suspension with a few strategically-placed zip ties.

It has managed to survive running into scenery a few times and being kicked by actors more than once. It only failed to make an entrance once in the run -- due to the antenna on the transmitter being snapped off thus limiting control range to about two feet. That required a last-minute frantic repair with brass tube, epoxy, and a quickly-soldered wire to bridge the gap.

The lights also failed once -- in the same performance the projector douser failed -- and this is exemplar of what I was talking about. There is a real difference between a "hacked" solution that will last for a quick shoot or the first day of a convention, and an engineered solution that will work reliably through a five-week run.

The best thing I can say about the douser is that it was already built. I had to rip off the flag and epoxy up a new one to fit the particular projector, and I had to modify the software to use an external switch instead of an external button, but that took under an hour. The rest of the servo housing and power supply and software and so forth was already built.

If nothing else, this proofed the concept of having ready-to-go solutions. My Duck Remote is the same; the XBee solution was already built and programmed and all it took to get to technical rehearsal was cramming the electronics into a different housing. (On the other hand, I did spend several days making a different software solution so as to simplify the hardware end -- and that only partially worked). But as robust as my devices are, they still fall short of the reliability I desire.

I don't at this point know if the douser fouled, overheated, or if the servo needs to be lubricated, but it failed once and the servo is visibly and audibly sticking at one point in its travel. Probably, if I simply swap out the servo for a new one it will make it to the end of the run without further failures, but that underlines the point. I simply can not trust it to keep working for an indeterminate amount of time. And I lack knowledge on how it failed, thus I can neither change it so it doesn't fail, or even predict mean time till the next failure.

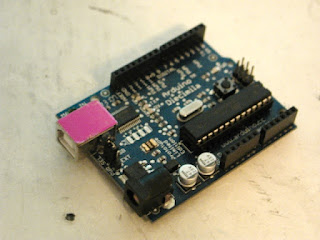

In the case of the robot, I do not know why the lights failed. In establishing communication with the onboard Arduino to interrogate it over serial monitor I reloaded the software. And it started working again and hasn't failed since. So I don't know what happened. The only suspicion is that somehow the software got corrupted. But it is also possible that it doesn't always boot up correctly, or that there is a loose connection that fixed itself while I was jiggling the unit to get access to the USB port.

Again, I don't know, so I don't have any way of either fixing it or predicting when it will break again.

On the gripping hand, of course, commercial devices fail all the time. We have a gobo rotator in the show which has failed in most performances. One of the bubble machines already quit. So for all the jerry-rig aspect of my robot, it has shown to be doing a more complex job in a more reliable way.

And of course all these devices are leveraging existing commercial modules. XBee modules and the Zigbee protocol and the underlying 802.15.4 standard. Servo motors, with gear trains and position sensors already integrated. Arduino, of course; that artist-friendly open-hardware, free software embedded computing solution. And even the lowly chain-store R/C car, building on decades of experience building playable remote-control toys.

As I implied earlier, the costumes are coming apart, set decorations are peeling off, props are breaking...my electronics are nowhere near the least reliable elements in the production. But in a larger perspective, all of these are also hacks. Making costume pieces with unusual and often untried materials, making props with re-purposed materials, and so forth. Theater is always about making things work outside of their usual context, and replacing what can't be afforded (or carried, or whatever) with something else.

Every kingly palace with marble floors and gilded throne is of course cunningly painted plywood. The jewels are resin-cast, the swords pot-metal, the armor is vacuuform plastic reinforced with medical cast material (aka celastic). The rocks are made of expanded polystyrene foam.

What the key lesson is, is that it isn't about the technology; it is about the process. Too much in a production like the one I'm currently mixing depends on guesswork about poorly-understood materials and processes, and risk-taking that these elements will function from night to night.

Theater does not need fewer hackers. What it needs is more engineers.

(It also needs to schedule the time to apply an engineering process. As an area set designer once put it, if whatever improvisation you've done makes it through dress rehearsal, the show will close with it. There is never time or energy or money to come back to something that works -- even if poorly -- and rebuild it. But engineering a solution requires a cycle of development and testing. The only way this really happens in theater is over the length of a season, or a career; what worked once, is refined and improved for the next show down the road. What is lacking, though, is still the analytical approach to finding out the parameters of why it worked when it did and describing the envelop of where it won't work. To do that you need more than simple empiricism.)

I'm in the middle of the run of a very complicated show that was thrown together too fast on too small a budget, by a company that has fallen in to a pattern of doing that. The props and effects, some of the costumes and set dressing, and other basic technical elements are held together with gaff tape and hot glue.

My robot is one of these elements. Although I spent the money and did the research for a robust chassis and control linkage, what we had time for is a $40 R/C car chassis carrying the lightest extruded-foam body I could build on top of it. Even a fiberglas shell would be too heavy for the undersized motor -- and at that, I had to tighten the suspension with a few strategically-placed zip ties.

It has managed to survive running into scenery a few times and being kicked by actors more than once. It only failed to make an entrance once in the run -- due to the antenna on the transmitter being snapped off thus limiting control range to about two feet. That required a last-minute frantic repair with brass tube, epoxy, and a quickly-soldered wire to bridge the gap.

The lights also failed once -- in the same performance the projector douser failed -- and this is exemplar of what I was talking about. There is a real difference between a "hacked" solution that will last for a quick shoot or the first day of a convention, and an engineered solution that will work reliably through a five-week run.

The best thing I can say about the douser is that it was already built. I had to rip off the flag and epoxy up a new one to fit the particular projector, and I had to modify the software to use an external switch instead of an external button, but that took under an hour. The rest of the servo housing and power supply and software and so forth was already built.

If nothing else, this proofed the concept of having ready-to-go solutions. My Duck Remote is the same; the XBee solution was already built and programmed and all it took to get to technical rehearsal was cramming the electronics into a different housing. (On the other hand, I did spend several days making a different software solution so as to simplify the hardware end -- and that only partially worked). But as robust as my devices are, they still fall short of the reliability I desire.

I don't at this point know if the douser fouled, overheated, or if the servo needs to be lubricated, but it failed once and the servo is visibly and audibly sticking at one point in its travel. Probably, if I simply swap out the servo for a new one it will make it to the end of the run without further failures, but that underlines the point. I simply can not trust it to keep working for an indeterminate amount of time. And I lack knowledge on how it failed, thus I can neither change it so it doesn't fail, or even predict mean time till the next failure.

In the case of the robot, I do not know why the lights failed. In establishing communication with the onboard Arduino to interrogate it over serial monitor I reloaded the software. And it started working again and hasn't failed since. So I don't know what happened. The only suspicion is that somehow the software got corrupted. But it is also possible that it doesn't always boot up correctly, or that there is a loose connection that fixed itself while I was jiggling the unit to get access to the USB port.

Again, I don't know, so I don't have any way of either fixing it or predicting when it will break again.

On the gripping hand, of course, commercial devices fail all the time. We have a gobo rotator in the show which has failed in most performances. One of the bubble machines already quit. So for all the jerry-rig aspect of my robot, it has shown to be doing a more complex job in a more reliable way.

And of course all these devices are leveraging existing commercial modules. XBee modules and the Zigbee protocol and the underlying 802.15.4 standard. Servo motors, with gear trains and position sensors already integrated. Arduino, of course; that artist-friendly open-hardware, free software embedded computing solution. And even the lowly chain-store R/C car, building on decades of experience building playable remote-control toys.

As I implied earlier, the costumes are coming apart, set decorations are peeling off, props are breaking...my electronics are nowhere near the least reliable elements in the production. But in a larger perspective, all of these are also hacks. Making costume pieces with unusual and often untried materials, making props with re-purposed materials, and so forth. Theater is always about making things work outside of their usual context, and replacing what can't be afforded (or carried, or whatever) with something else.

Every kingly palace with marble floors and gilded throne is of course cunningly painted plywood. The jewels are resin-cast, the swords pot-metal, the armor is vacuuform plastic reinforced with medical cast material (aka celastic). The rocks are made of expanded polystyrene foam.

What the key lesson is, is that it isn't about the technology; it is about the process. Too much in a production like the one I'm currently mixing depends on guesswork about poorly-understood materials and processes, and risk-taking that these elements will function from night to night.

Theater does not need fewer hackers. What it needs is more engineers.

(It also needs to schedule the time to apply an engineering process. As an area set designer once put it, if whatever improvisation you've done makes it through dress rehearsal, the show will close with it. There is never time or energy or money to come back to something that works -- even if poorly -- and rebuild it. But engineering a solution requires a cycle of development and testing. The only way this really happens in theater is over the length of a season, or a career; what worked once, is refined and improved for the next show down the road. What is lacking, though, is still the analytical approach to finding out the parameters of why it worked when it did and describing the envelop of where it won't work. To do that you need more than simple empiricism.)

Wednesday, July 18, 2012

The Man Who Mistook His Mic for a Hat Stand

I'm using a mic for a hatstand. Sm58 in a straight round-base stand. Works pretty well. The PA just came back from a gig and there's no room in the closet to store all of it.

Doesn't help that the robot worktable is still set up and I have carving foam, paint, plastic bits, and of course electronics strewn around. I really need to move some projects from "in progress" to "done and can be put on a shelf out of the way."

Lacking the time and space for that, I'm putting more things in boxes today. So at least the half-done project has all the essential parts collected in one place. One such (large) box is filled with vacuumform Lewis Gun. Which spills over into another box, which also contains grenade spoons and other parts to build some prop smoke grenades.

On the table is the camera head we didn't use for the robot. I'm half-tempted to keep it. And instead of pulling out the mini servo, program an AVR to do random moves.

Actually, if I was doing random robotics that had any connection to the show I just opened, I'd be putting proximity/movement sensors in a basic servo to build a couple of what the BEAM community calls Head-type Squirmers. And then I'd put a big foam-core cube on the servo and paint it up like a candy. Which is to say; I'd be building some "Square candies that look 'round."

It is awfully tempting. I have all the hardware here. If I skipped active tracking and just had pre-programmed behavior linked to a simple IR proximity sensor.....

Argh! My goal for today was actually to log hours in element repair. I'm getting paid for that, at least. And I need some spares for the weekend. The other goal before the next weekend of the show begins is upgrades to the robot. And with my Vex apparently dead I was going to leverage the two new XBee nodes I just picked up.

The second test was going to be -- hopefully still will be -- trying out direct mode for control of a servo. I've seen it done as a demonstration at Makers Faire. Apparently the PCM output of the analog pins is close enough to drive an un-modified servo. And all you need for the transmitter side is a potentiometer. Of course, adding a couple trim resistors/pots would be smart.

I still prefer -- especially for something as fragile as my robot -- to set the servo limits in software. And this also means that if you are transmitting power on/power off signals to the lights and wireless camera (which draws power from the 7.2 nicads in the chassis), you can transmit a single "toggle" command instead of having to depend on continuous transmission of either the "on" command or a "kill" function. Plus, the eyes were wired with six high power LED's each in 3 colors, and with a micro somewhere in the signal chain you could command these to color mix or to chase.

All I really hope to get done by this weekend's shows is adding a camera and light kill switch, though. Which I can probably do with no more than my existing XBee nodes and the "Really" (aka "Relay") board I purchased from one of the Kowloon-based electronics suppliers via eBay.

The coolest way to do it is, of course, with full serial. Although I/O line passing on the XBee nodes is near-transparent and simple to set up, establishing a serial link gives a more robust link and a practically unlimited command set. Plus, of course, having client-side intelligence means you can program the thing to operate autonomously between commands. On the server side, set up an Arduino/AVR and wire that to buttons and switches. Or write an application in Processing and put in virtual buttons and switches/monitor keyboard and mouse.

This is more of the sort of thing I taught myself about "naked" AVRs for, so I didn't have to waste a whole $28 Arduino on an embedded application. But I'm not fluent and practiced enough with them so I can quickly write some serial data routines for the built-in UART and upload it to a 45-cent chip. It might only be basic C, but straight C is worlds away from Wiring (aka Processing/Arduino) wrapped inside that handy IDE. When you are programming for micros, you lose much of that layer of abstraction between you and the metal -- "Serial.print ("hello, world");" begins to look a lot more like "PORTB |= (0 << 2);"

Well. Maybe if I can get stuff boxed and the table cleared and XBees show they have the right firmware and the servo responds...I might hook up the IR proximity detector I have and see how fast I could make a "square candy that looks 'round."

Doesn't help that the robot worktable is still set up and I have carving foam, paint, plastic bits, and of course electronics strewn around. I really need to move some projects from "in progress" to "done and can be put on a shelf out of the way."

Lacking the time and space for that, I'm putting more things in boxes today. So at least the half-done project has all the essential parts collected in one place. One such (large) box is filled with vacuumform Lewis Gun. Which spills over into another box, which also contains grenade spoons and other parts to build some prop smoke grenades.

On the table is the camera head we didn't use for the robot. I'm half-tempted to keep it. And instead of pulling out the mini servo, program an AVR to do random moves.

Actually, if I was doing random robotics that had any connection to the show I just opened, I'd be putting proximity/movement sensors in a basic servo to build a couple of what the BEAM community calls Head-type Squirmers. And then I'd put a big foam-core cube on the servo and paint it up like a candy. Which is to say; I'd be building some "Square candies that look 'round."

It is awfully tempting. I have all the hardware here. If I skipped active tracking and just had pre-programmed behavior linked to a simple IR proximity sensor.....

Argh! My goal for today was actually to log hours in element repair. I'm getting paid for that, at least. And I need some spares for the weekend. The other goal before the next weekend of the show begins is upgrades to the robot. And with my Vex apparently dead I was going to leverage the two new XBee nodes I just picked up.

The second test was going to be -- hopefully still will be -- trying out direct mode for control of a servo. I've seen it done as a demonstration at Makers Faire. Apparently the PCM output of the analog pins is close enough to drive an un-modified servo. And all you need for the transmitter side is a potentiometer. Of course, adding a couple trim resistors/pots would be smart.

I still prefer -- especially for something as fragile as my robot -- to set the servo limits in software. And this also means that if you are transmitting power on/power off signals to the lights and wireless camera (which draws power from the 7.2 nicads in the chassis), you can transmit a single "toggle" command instead of having to depend on continuous transmission of either the "on" command or a "kill" function. Plus, the eyes were wired with six high power LED's each in 3 colors, and with a micro somewhere in the signal chain you could command these to color mix or to chase.

All I really hope to get done by this weekend's shows is adding a camera and light kill switch, though. Which I can probably do with no more than my existing XBee nodes and the "Really" (aka "Relay") board I purchased from one of the Kowloon-based electronics suppliers via eBay.

The coolest way to do it is, of course, with full serial. Although I/O line passing on the XBee nodes is near-transparent and simple to set up, establishing a serial link gives a more robust link and a practically unlimited command set. Plus, of course, having client-side intelligence means you can program the thing to operate autonomously between commands. On the server side, set up an Arduino/AVR and wire that to buttons and switches. Or write an application in Processing and put in virtual buttons and switches/monitor keyboard and mouse.

This is more of the sort of thing I taught myself about "naked" AVRs for, so I didn't have to waste a whole $28 Arduino on an embedded application. But I'm not fluent and practiced enough with them so I can quickly write some serial data routines for the built-in UART and upload it to a 45-cent chip. It might only be basic C, but straight C is worlds away from Wiring (aka Processing/Arduino) wrapped inside that handy IDE. When you are programming for micros, you lose much of that layer of abstraction between you and the metal -- "Serial.print ("hello, world");" begins to look a lot more like "PORTB |= (0 << 2);"

Well. Maybe if I can get stuff boxed and the table cleared and XBees show they have the right firmware and the servo responds...I might hook up the IR proximity detector I have and see how fast I could make a "square candy that looks 'round."

Tuesday, July 17, 2012

Vexing

Ah, the joy of embedded computing -- when you are debugging you can never be sure if it is really a software error or if it is a hardware problem instead.

The two worlds blend into each other, too. Often the simplest "test circuit" is dashing off a quick program that will interrogate the inputs or run through a preset motion on a servo. So you find yourself working at both ends at once; with breadboard and alligator clips and double-stick tape on the desktop, and a couple feet away, similar commented-out and patched together boilerplate code running on a laptop.

I have three gadgets in performance right now. My XBee, in a new housing and with a new software interpreter, is in a children's show. Amusingly enough, the Easy Button it used to be in is in another show, sans electronics. My MIDI-controlled projector douser is in its first show, and is a visible lighting effect. The MIDI circuit is being bypassed, though, making it basically the world's most complicated solenoid. Good thing I included a quarter-inch jack for direct control (although I had to tweak the software to use it for this show). And the R/C robot with wireless camera is also in a show.

And it needs work. The transmitter is barely strong enough. The wheels and motors are so weak I'm scared it is going to stall out in the middle of a performance. And I could really use remote switches for the lights and camera. The latter, at least, I could hack up pretty fast with one of the new XBee nodes I just ordered. Pretty much a button and a Darlington transmitter and that old friendly pin echo mode would do it.

Which I may need to. I spent today trying to get the Vex transmitter I purchased to communicate with an Arduino. At this point about all I am sure of is that the receiver is getting power, and seems to put out at least one pulse distinct enough to trigger the Arduino's interrupt. Other than that, no joy.

For the first time in the two years since I got rid of it, I could use that old oscilloscope. I can't confirm that the receiver is actually working correctly, or seeing the transmitter.

The alternative (outside of ordering a second one and seeing if that one works better) is to delve a lot deeper into the Arduino PCM capabilities. Basically, write a series of sketches to confirm that the receiver is actually sending something like protocol. And then either go back through the code I've been trying to use, or write new code from scratch.

And I still don't know if the other end -- interfacing with the Futaba ESC and the steering servo, or even interfacing with the LED controller darlingtons -- will be as easy as hoped or will bring yet another software/hardware debug.

There isn't THAT much time this week. I have to re-do some sound cues and repair a whole bunch of microphone elements, plus I should really make some new mic belts. And I have a multi-track mixdown to do. And, after all that is done, it would be very, very nice to do some work I'll actually get PAID for!

Looks like it was a hardware error after all -- and not on my side. I hooked up a speaker and I don't seem to be getting regular tone bursts. I hooked it up to the Vex CPU and the Receiver Status light doesn't light. Still not as good as hooking up an oscilloscope, but I'm willing at this point to drop the $40 on a replacement receiver. Except that I am flat broke again (the current design is paying in installments) so I can't do that until the end of the month. By which point the show will be almost over.

The two worlds blend into each other, too. Often the simplest "test circuit" is dashing off a quick program that will interrogate the inputs or run through a preset motion on a servo. So you find yourself working at both ends at once; with breadboard and alligator clips and double-stick tape on the desktop, and a couple feet away, similar commented-out and patched together boilerplate code running on a laptop.