I was handed a kit to assemble and paint. I'd just been introduced to laser cutting and engraving, though, and I thought I could pimp it up a little.

I was handed a kit to assemble and paint. I'd just been introduced to laser cutting and engraving, though, and I thought I could pimp it up a little.The experiments worked. Well enough I ended up documenting the project for Instructables. And that's where the trouble started.

Enough people at Instructables showed an interest that I made my files available. Since some of the parts weren't originally mine, I had to come up with designs for those, as well.

It was through Instructables that I was contacted by the master of a Jedi Temple, wanting a custom design made for his students. I agreed to work on it. Many emails and iterations and a full free kit shipped out no charge and I stopped being able to shake the feeling that he wasn't actually going to be good for the cost of the final kits. So I parted ways with that customer.

Since I now had a new and tested shell design I tried for a while to generate a new holocron based around it. But I didn't like (and still don't like) and of the results.

The holocron does not yet appear in any movie. It appears in some games and animations; one appearance being the best documented appearance I've been able to find. This natural goal was blocked, however, by the seeming impossibility of achieving it with the materials at hand. So I continued tinkering with other alternate designs, trying to fold in various motifs from the Star Wars universe.

It was at that juncture that I opened an interest thread at the Replica Props Forum. I got strong interest there, but still couldn't satisfy myself with the design.

Took a break to work on other projects. Did the Retro Raygun, some other things. My Croft necklace was also a hit, and I gave it away on long-term loan, which led me to starting the Wraith Stone project, and that looked to require some advanced electronics, so I picked up the holocron project again just to be able to work out the charge circuit and load sharing and surface-mount issues on a simpler board than what I intended for the Wraith Stone.

And when I returned to the holocron, what I had seen as an unsolvable problem turned out to be trivial. The critical insight might have been a function introduced on the new lasers just installed at TechShop; vector engraving. In any case, I immediately moved to front position a design much more closely based on that one animation.

It is just different enough from my first holocron, though, that the lighting didn't look right anymore. So back to some very basic development to rethink how the lighting circuit interacts.

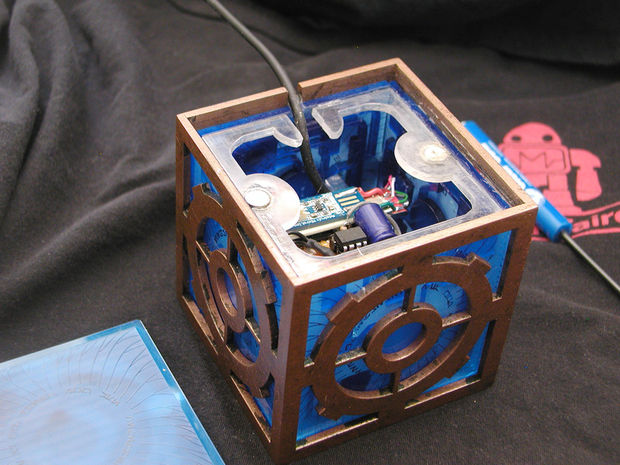

And, of course, late in the day I realized there were possible ways to get it to look even more like my selected source. The very first holocron was a three-layer model; painted shell, solid diffusion layer, then the vector-cut "circuit" layer. I finally broke through this paradigm -- first through having to add a diffusor cube, then through realizing an inner "hypercube" might be an even closer match to what was seen on screen.

And, of course, late in the day I realized there were possible ways to get it to look even more like my selected source. The very first holocron was a three-layer model; painted shell, solid diffusion layer, then the vector-cut "circuit" layer. I finally broke through this paradigm -- first through having to add a diffusor cube, then through realizing an inner "hypercube" might be an even closer match to what was seen on screen.And that's where I am right now; cutting out yet more test pieces to see if this idea works out, while my growing list of confirmed customers are demanding I let them give me money...

Which is of course the absolutely perfect time for a major change at my day job.