I need to move the Jubal Early further back. Too many other projects with firmer due dates, and a bit too broke this month for 1/2" slabs of aluminium plate, 1/4" ballnose endmills, and a renewal on my TechShop membership.

I need to move the Jubal Early further back. Too many other projects with firmer due dates, and a bit too broke this month for 1/2" slabs of aluminium plate, 1/4" ballnose endmills, and a renewal on my TechShop membership.Before I take a break on it, though, I want to get the model up to a show-off point.

The next step, though, is going slow. Like several recent props, the Jubal Early was built to use an available after-market grip. From research, specifically the Pachmayr Decelerator, in Smith&Wesson N-frame.

Trouble is, I can't find a proper scaled drawing of the actual gun frame (not one that allows me to properly import the curves into the CAD file). And I'm unwilling to cut apart a $30 pair of grips in order to scan the interior.

So I'm in the process of cutting a mock-up frame out of MDF, which I'll fit by trial and error. When that is finally right, I'll scan that in with a scale reference, and then build the CAD to that.

Another thing that is going to take time. There are several decorative screws. I don't know what size they are. Since a lot of catalogs don't bother mentioning the size of the head of a screw, I may have to purchase a selection from different manufacturers and measure them against the reference photographs until I have the right ones.

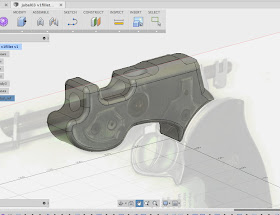

So even getting this up to the point of machining is going to take a while. The main body alone (seen above) needs to be flipped so I can cut from both sides, and then will probably need several manual machining processes; tapping screw holes, doing the through drill for barrel, and probably cutting a deep slot for the other parts to fit inside.

And as much as I am liking Fusion 360 so far, I think the CAM options on it may be too primitive for this. I didn't even see (on the one tutorial I've watched so far) anything on how to create support tabs. At the very least, I'm going to be pushing this through Cut3d (TechShop has licensed copies of that running on their machines), and I might even want to port to Inventor CAD for the final steps of prepping to machine.

And as much as I am liking Fusion 360 so far, I think the CAM options on it may be too primitive for this. I didn't even see (on the one tutorial I've watched so far) anything on how to create support tabs. At the very least, I'm going to be pushing this through Cut3d (TechShop has licensed copies of that running on their machines), and I might even want to port to Inventor CAD for the final steps of prepping to machine.I have to say; the Babylon5 PPG is looking easier and easier, relative to this one. The simple look of this thing masks that most of these cuts and rounded edges are tough to achieve in a controlled manner. This is an easy prop to hack out of a couple chunks of wood. It is a tough prop to machine to a high degree of polish out of proper metals.

No comments:

Post a Comment